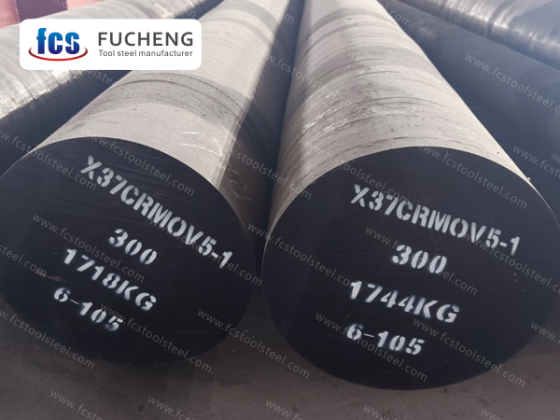

AISI H11 Tool Steel | 1.2343 | X37CrMoV5-1 | SKD6 | BH11

As an air-cooled hardening type hot work die steel, H11 steel has excellent high-temperature strength and toughness. Its chromium molybdenum vanadium alloy system endows it with excellent heat fatigue resistance and wear resistance. H11 steel maintains high hardness under 500-600 ℃ working conditions, while also having good cutting and heat treatment stability, making it particularly suitable for the manufacturing of aluminum/magnesium alloy die-casting molds and hot forging dies.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

H11 STEEL

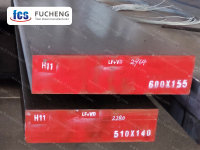

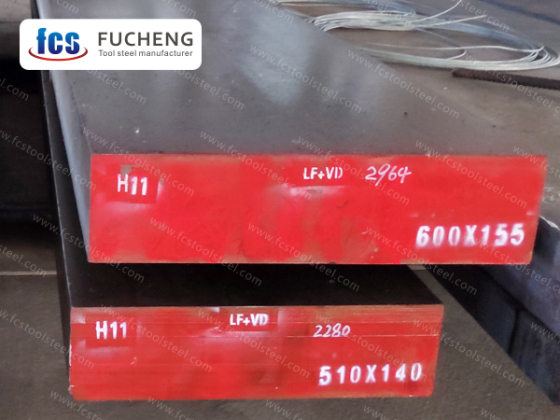

| Smelting and Manufacture Method: | LF+VD+(ESR)+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤229 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

H11 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ASTM | H11 | 0.33~0.43 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.60 | 0.30~0.60 |

| DIN/W-Nr. | X38CrMoV5-1/1.2343 | 0.36~0.42 | 0.90~1.20 | 0.30~0.50 | 4.80~5.80 | 1.10~1.40 | 0.25~0.50 |

| JIS | SKD6 | 0.32~0.42 | 0.80~1.20 | ≤0.50 | 4.50~5.50 | 1.00~1.50 | 0.30~0.50 |

APPLICATION

H11 steel is widely used in the field of hot work mold manufacturing, especially suitable for high-temperature working conditions such as die-casting molds, hot forging molds, and extrusion molds. The excellent heat resistance and thermal fatigue resistance of H11 steel make it outstanding in aluminum alloy, magnesium alloy die-casting, and automotive parts hot forming, and can withstand high temperature repeated impacts below 600 ℃.

H11 steel is also commonly used in high-precision injection molds, especially for the molding of engineering plastics and optical grade plastics that require long-term stable production. The excellent polishing and wear resistance of H11 steel ensure long-lasting surface smoothness of the mold, reduce maintenance requirements, and are suitable for high demand injection molding production in industries such as electronics and home appliances.

H11 steel is also used in the manufacture of industrial cutting tools and wear-resistant components, such as hot shear knives, high-temperature fixtures, and extruder screws. The high toughness and wear resistance of H11 steel enable it to maintain excellent performance even under heavy loads and high temperatures, making it widely used in the fields of mechanical processing and high-temperature equipment manufacturing.

H11 STEEL CHARACTERISTICS

H11 steel exhibits excellent thermal stability and can maintain structural stability under repeated heating and cooling conditions. Its unique alloy composition ratio enables the material to maintain excellent strength performance even in high-temperature environments.

H11 steel has outstanding thermal fatigue resistance and is particularly suitable for withstanding rapid cooling and heating conditions in die-casting molds. After appropriate heat treatment, the internal grain structure of H11 steel can effectively suppress the propagation of hot cracks.

In terms of wear resistance, H11 steel achieves good wear resistance through uniform distribution of carbides. The balanced design of hardness and toughness ensures that the mold has both service life and impact resistance.

The heat treatment adaptability is a significant advantage of H11 steel, and a hardness range from 50HRC to 55HRC can be obtained through different processes. This flexibility meets the differentiated needs of various molds.

In terms of processing performance, H11 steel has excellent machinability in the annealed state. This feature significantly reduces the processing difficulty and cost in the mold manufacturing process.

The tempering resistance enables H11 steel to maintain stable hardness during long-term high-temperature operation. This characteristic plays a decisive role in extending the service life of molds.

The heat shock resistance of H11 steel is attributed to its moderate thermal conductivity and thermal expansion coefficient. This enables the mold to withstand severe temperature fluctuations without cracking easily.

Dimensional stability is another highlight of H11 steel, with minimal heat treatment deformation, making it particularly suitable for precision mold manufacturing. This feature ensures the dimensional accuracy and reusability of the mold.