4X5MΦC Hot Work Tool Steel

Сталь 4X5MΦC обладает высокой твердостью и ударной вязкостью и подходит для литья под давлением, экструзии, горячего прессования алюминия, меди, магния.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

4X5MΦC STEEL

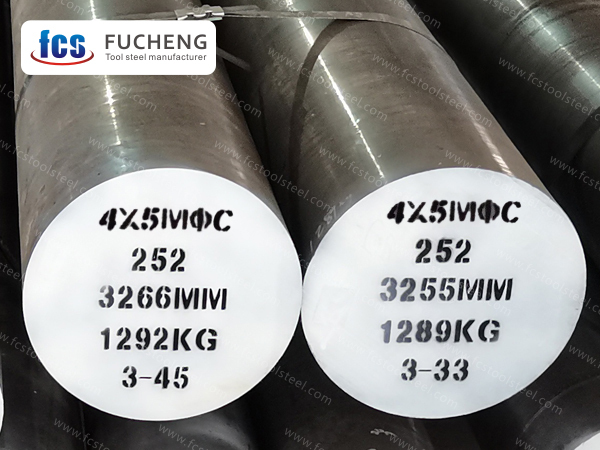

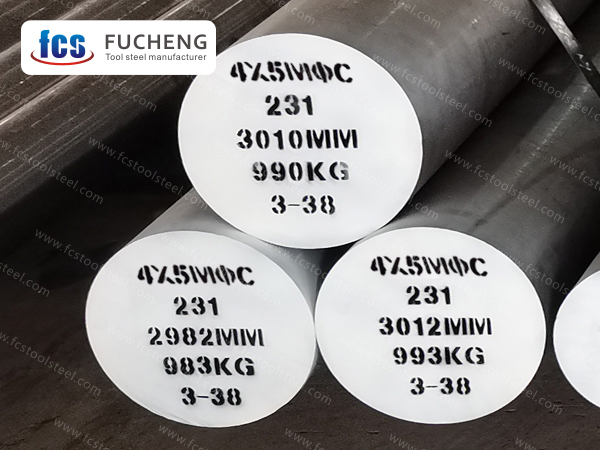

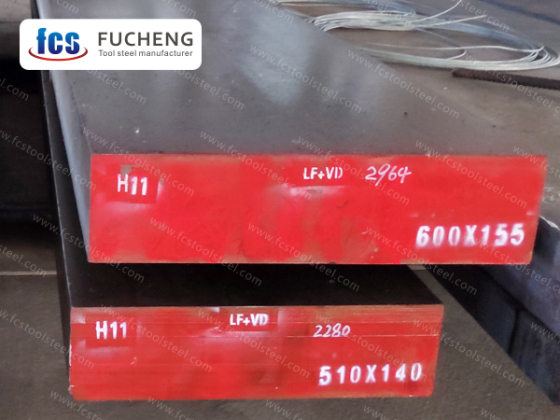

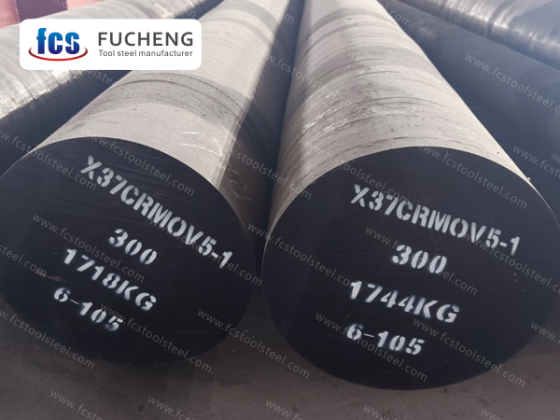

| Smelting and Manufacture Method: | LF+VD+ESR+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤229 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

4X5MΦC STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ГOСТ | 4X5MΦC | 0.33~0.42 | 0.80~1.20 | ≤0.50 | 4.60~5.50 | 1.10~1.50 | 0.25~0.55 |

| DIN/W-Nr. | X38CrMoV5-1/1.2343 | 0.33~0.41 | 0.80~1.20 | 0.25~0.50 | 4.80~5.50 | 1.10~1.50 | 0.30~0.50 |

| ASTM | H11 | 0.33~0.43 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.60 | 0.30~0.60 |

APPLICATION

4X5MΦC steel has high hardness and toughness, and is suitable for die casting die, extrusion die, hot pressing die of aluminum, copper, magnesium.

4X5MΦC STEEL CHARACTERISTICS

4X5MΦC steel is an alloy tool steel with special properties, which has important application value in the industrial field.

4X5MΦC steel is known for its excellent thermal stability and wear resistance, making it particularly suitable for working in high-temperature and high-pressure environments. This type of steel performs outstandingly in the mold manufacturing, forging, and die-casting industries, and can withstand repeated thermal cycles and mechanical impacts.

The alloy composition of 4X5MΦC steel has been carefully designed to maintain high hardness while still possessing good toughness. This balance makes it less prone to cracking or deformation under complex working conditions, extending the service life of the mold.

The heat treatment process of 4X5MΦC steel is crucial for its performance. By appropriate heat treatment, its microstructure can be optimized, further improving its resistance to thermal fatigue and overall strength, meeting more stringent industrial requirements.

4X5MΦC steel is widely used in the fields of automobile manufacturing and aerospace. For example, it is often used in the mold manufacturing of key components such as engine parts and turbine blades, ensuring high precision and long lifespan.

4X5MΦC steel has a higher cost-effectiveness compared to similar materials. Although some high-end alloys may perform better under extreme conditions, 4X5MΦC steel is already able to provide excellent performance and economic benefits in most industrial scenarios.

The future development of 4X5MΦC steel will focus on the application of surface modification technology. Through advanced coating and heat treatment technologies, its corrosion resistance and wear resistance can be further improved, expanding its application potential in emerging fields such as new energy and precision manufacturing.