- Home

- >

- Products

- >

- 4Cr5MoSiV Mold Steel

- >

4Cr5MoSiV Mold Steel

4Cr5MoSiV mold steel has good thermal strength and heat fatigue resistance, and can maintain stable performance under high temperature conditions. 4Cr5MoSiV mold steel is widely used in die-casting molds, injection molds, plastic molds and other fields.

- Fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

4Cr5MoSiV TOOL STEEL

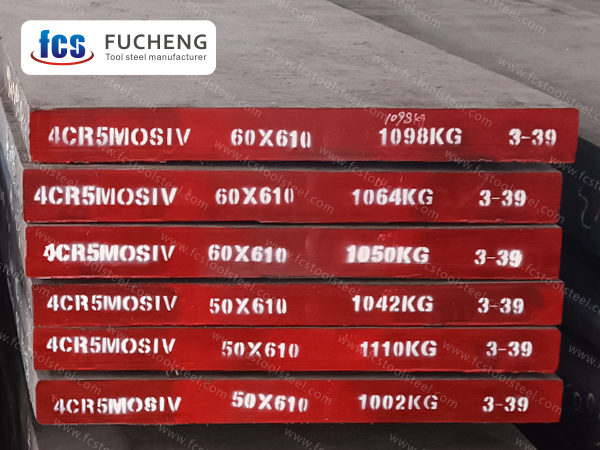

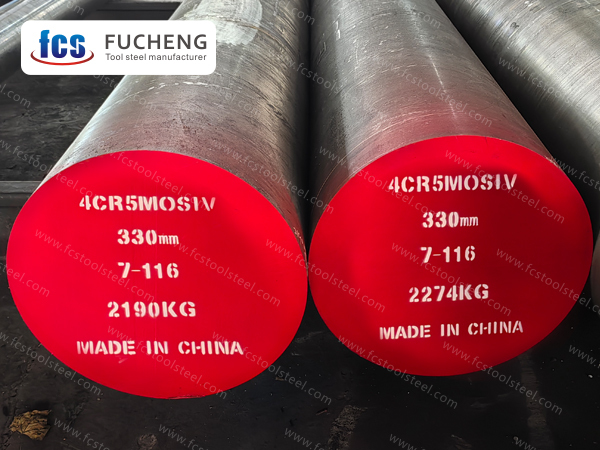

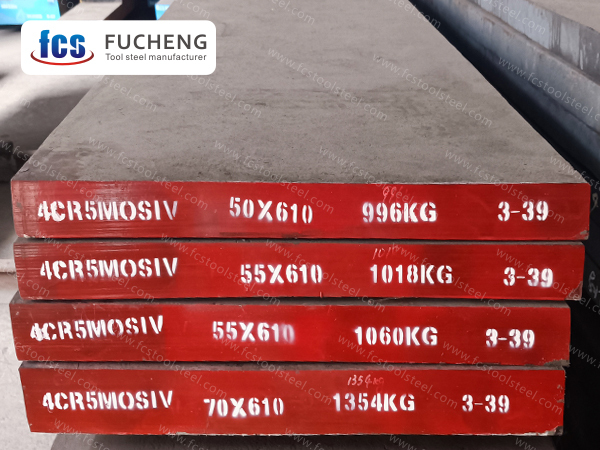

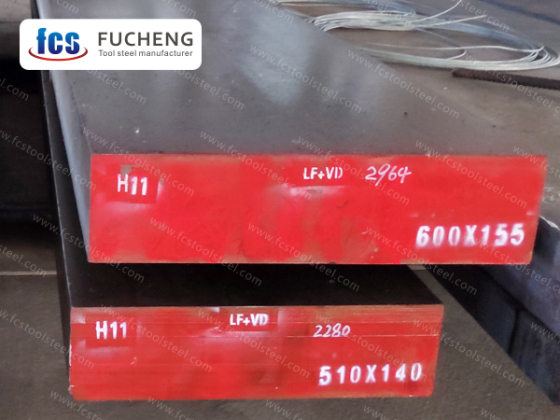

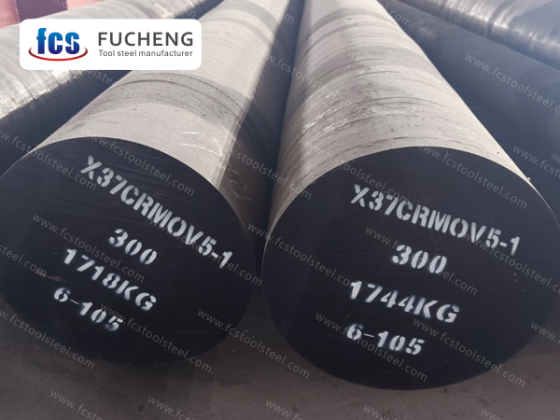

| Smelting and Manufacture Method: | LF+VD+ESR+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤229 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

4Cr5MoSiV STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| GB | 4Cr5MoSiV | 0.32~0.42 | 0.8~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.60 | 0.30~0.60 |

| DIN/W-Nr. | X38CrMoV5-1/1.2343 | 0.36~0.42 | 0.90~1.20 | 0.30~0.50 | 4.80~5.80 | 1.10~1.40 | 0.25~0.50 |

| ASTM | H11 | 0.33~0.43 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.60 | 0.30~0.60 |

| JIS | SKD6 | 0.32~0.42 | 0.80~1.20 | ≤0.50 | 4.50~5.50 | 1.00~1.50 | 0.30~0.50 |

APPLICATION

4Cr5MoSiV steel is widely used in the field of aluminum alloy die-casting molds. Its excellent heat fatigue resistance and resistance to molten metal erosion ensure stable operation of the mold under high temperature and high pressure, prolong its service life, and improve the accuracy of die-casting parts.

4Cr5MoSiV steel performs outstandingly in the manufacturing of hot extrusion tools and core rods. With high strength and high thermal stability, it can withstand severe friction and high-temperature deformation during metal extrusion, and is suitable for hot extrusion forming processes of copper alloys or aluminum alloys.

4Cr5MoSiV steel is an ideal choice for forging hammer forging dies and press forging dies. Its high toughness and thermal cracking resistance effectively resist forging impact loads, reduce the risk of mold failure in repeated thermal cycles, and are suitable for large-scale forging production of automotive parts and other components.

4Cr5MoSiV steel is used in high-speed precision forging dies and plastic compression molds. By optimizing the secondary hardening effect of heat treatment, this steel maintains high hardness and wear resistance, ensuring dimensional stability and surface smoothness during precision part forming.

4Cr5MoSiV Steel Characteristics

4Cr5MoSiV mold steel can maintain good hardness and strength at high temperatures, and is not easily softened or deformed. During the working process of the mold, even if it is exposed to high-temperature metal materials for a long time, stable performance can be maintained, thereby extending the service life of the mold.

4Cr5MoSiV mold steel has high toughness and can withstand large impacts and vibrations. During the use of molds, unexpected impacts such as the flow impact of metal materials may be encountered. This type of steel can better resist these impacts and reduce the risk of mold cracking.

The mold will constantly rub against the metal material during use, so it needs to have good wear resistance. After appropriate heat treatment, the surface hardness of 4Cr5MoSiV mold steel is high, which can effectively resist wear and maintain the dimensional accuracy and surface quality of the mold.

4Cr5MoSiV mold steel has good machinability and can be made into various shapes of molds through cutting, grinding and other processing methods. Meanwhile, it is relatively easy to control during the heat treatment process and can meet the performance requirements of different molds.