- Home

- >

- Products

- >

- 1.2343 Tool Steel

- >

1.2343 Tool Steel

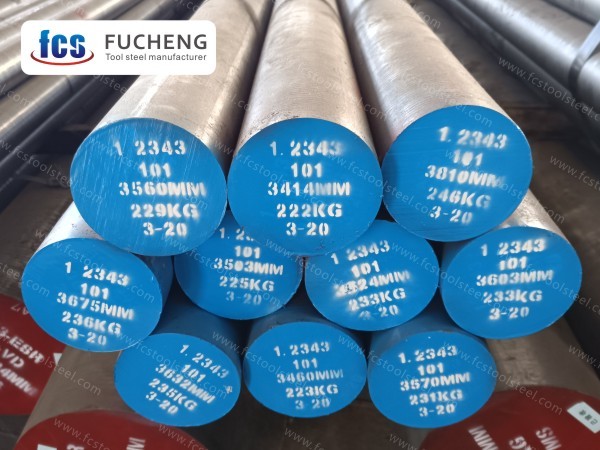

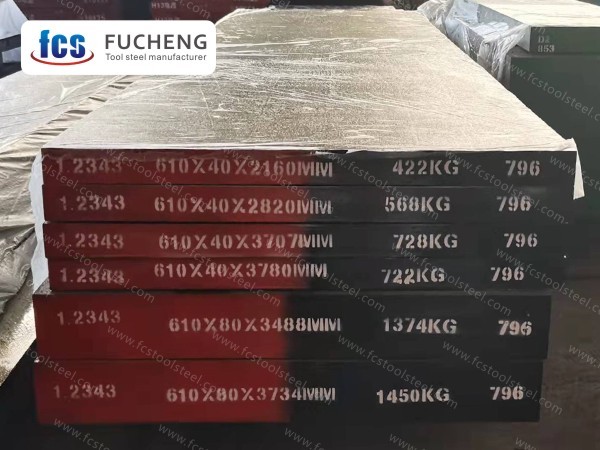

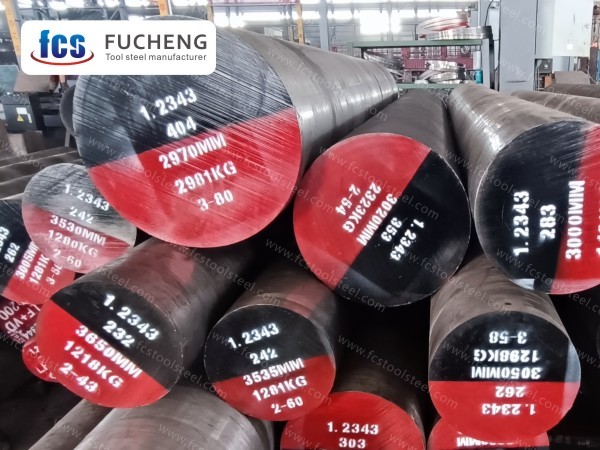

1.2343 steel is a hot work die steel with high toughness and wear resistance. Its core advantages lie in excellent heat fatigue resistance and high-temperature strength. 1.2343 steel is very suitable for high-temperature working environments such as die-casting and forging.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

1.2343 TOOL STEEL

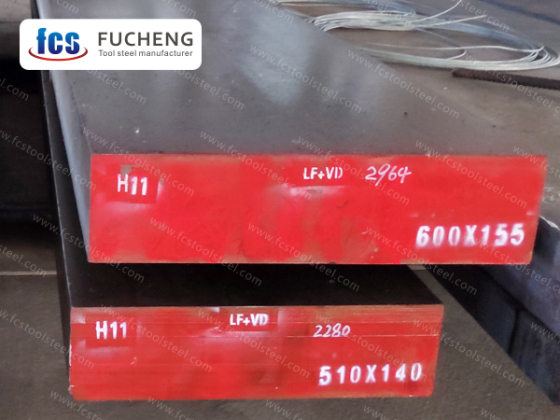

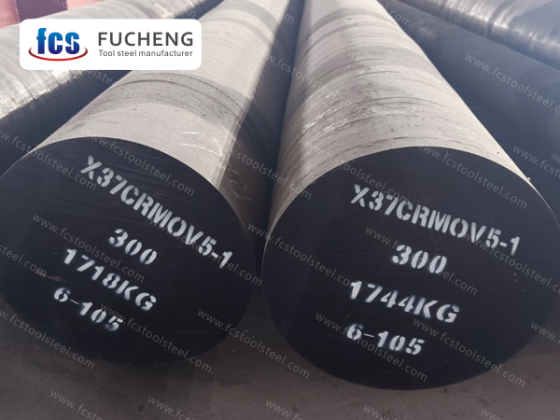

| Smelting and Manufacture Method: | LF+VD+ESR+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤229 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

1.2343 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| DIN/W-Nr. | X38CrMoV5-1/1.2343 | 0.36~0.42 | 0.90~1.20 | 0.30~0.50 | 4.80~5.80 | 1.10~1.40 | 0.25~0.50 |

| ASTM | H11 | 0.33~0.43 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.60 | 0.30~0.60 |

| JIS | SKD6 | 0.32~0.42 | 0.80~1.20 | ≤0.50 | 4.50~5.50 | 1.00~1.50 | 0.30~0.50 |

APPLICATION

1.2343 steel is suitable for aluminum alloy, zinc alloy die-casting die, extrusion die, cold blanking and hot shearing.

1.2343 Steel Characteristics

1.2343 steel has good toughness, thermal strength, and thermal fatigue properties, which can be air cooled and hardened. It can be air quenched at lower austenitizing temperatures with small heat treatment deformation and low oxidation tendency during air quenching, and can resist the erosion effect of molten aluminum.

1.2343 steel has high strength and hardness, making it suitable for manufacturing important parts that withstand large loads and stresses, such as turbine discs in aircraft engines, compressor blades, high-speed train axles, etc. In addition, due to its good toughness and fatigue resistance, it can also be used to manufacture key components such as connecting rods and crankshafts in engineering machinery such as automobiles and tractors.

The processing performance of 1.2343 steel is good, and it can be formed by methods such as forging, rolling, and extrusion. During forging, due to its lower forging temperature and shorter insulation time, oxidation and decarburization phenomena during the forging process can be reduced, and the surface quality and internal organizational uniformity of the forging can be improved. When rolling, hot or cold rolling processes can be used to meet the size and performance requirements of different products. During extrusion, precise control of product shape and size can be achieved by controlling the extrusion ratio and extrusion speed.

1.2343 steel has good welding performance and can be welded using methods such as arc welding, gas shielded welding, laser welding, etc. Before welding, strict preheating and post heat treatment should be carried out to eliminate welding stress and improve weld microstructure. During the welding process, attention should be paid to controlling welding parameters to avoid welding defects such as overheating and overheating. After welding, strict non-destructive testing and mechanical performance testing should be carried out to ensure the quality of the welded joint.

The heat treatment process of 1.2343 steel is relatively complex, usually requiring multiple processes such as quenching and tempering. When quenching, appropriate quenching medium and quenching temperature should be selected based on the performance requirements of the product to ensure the ideal martensitic structure is obtained. When tempering, appropriate tempering temperature and time should be selected based on the product's usage environment and performance requirements to adjust the hardness and toughness of the steel. In addition, surface hardness and wear resistance of 1.2343 steel can be further improved through surface treatment processes such as carburization and nitriding.

During the use of 1.2343 steel, attention should be paid to preventing corrosion and wear. Corrosion is mainly caused by chemical reactions between alloy elements in steel and oxygen, moisture, etc. in the environment. To prevent corrosion, methods such as coating and coating can be used to treat the steel surface. Wear is mainly caused by physical effects such as shear and friction on the surface material of steel during the stress process. To reduce wear, methods such as lubrication and wear-resistant coatings can be used to treat the steel surface.

In summary, 1.2343 steel is an alloy steel with high strength, high hardness, good toughness, and fatigue resistance, widely used in the manufacturing of key components in aviation, aerospace, automotive, mechanical and other fields. By studying and applying the processing performance, welding performance, heat treatment process, and other aspects of 1.2343 steel, its product quality and usability can be further improved to meet the technical requirements of different industries and fields.