- Home

- >

- Products

- >

- X40CrMoV5-1 Steel

- >

X40CrMoV5-1 Steel

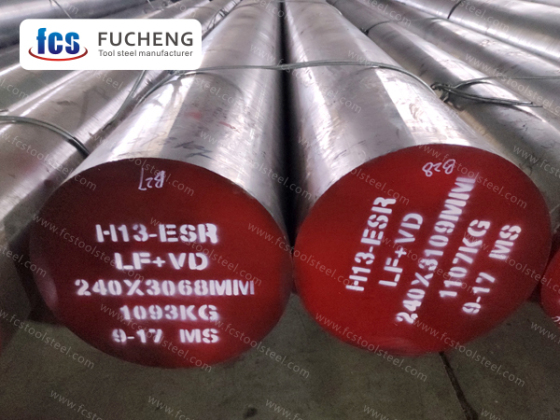

X40CrMoV5-1 steel, as a hot work die steel, is characterized by its excellent high-temperature performance combination, which combines high toughness and high-temperature strength, making it particularly suitable for repeated thermal cycling conditions such as die-casting molds; X40CrMoV5-1 steel undergoes electroslag remelting process to ensure material uniformity, and with optimized heat treatment process, it can achieve 48-52HRC hardness. X40CrMoV5-1 steel has excellent resistance to thermal fatigue, aluminum/copper alloy erosion, and extremely low heat treatment deformation rate. After surface nitriding treatment, the hardness can reach HV1000 or above, significantly extending the mold life.

- Fucheng Steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

- Download

X40CrMoV5-1 TOOL STEEL

| Smelting and Manufacture Method: | LF+VD+ESR+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤235 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

X40CrMoV5-1 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| DIN/W-Nr. | X40CrMoV5-1/1.2344 | 0.35~0.42 | 0.90~1.20 | 0.30~0.50 | 4.80~5.50 | 1.20~1.50 | 0.90~1.15 |

| ASTM | H13 | 0.32~0.45 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.75 | 0.80~1.20 |

| JIS | SKD61 | 0.35~0.42 | 0.80~1.20 | 0.25~0.50 | 4.80~5.50 | 1.00~1.50 | 0.80~1.15 |

APPLICATION

X40CrMoV5-1 steel plays an important role in the field of die-casting mold manufacturing, and is particularly suitable for die-casting molding of non-ferrous metals such as aluminum magnesium alloys. X40CrMoV5-1 steel material exhibits excellent stability in high temperature environments and can withstand harsh working conditions of repeated heating and cooling, effectively preventing thermal fatigue cracks on the mold surface and ensuring long-term reliability.

X40CrMoV5-1 steel is commonly used in the manufacture of forging and extrusion molds. Its excellent impact toughness and wear resistance enable it to withstand huge mechanical stresses during metal forming processes. X40CrMoV5-1 steel can maintain mold dimensional accuracy even under continuous high-intensity working conditions, significantly extending tool service life.

X40CrMoV5-1 steel material is also widely used in the manufacturing of key components for plastic injection molds. After appropriate treatment, the surface of the mold can achieve excellent corrosion resistance, effectively resisting the erosion of plastic melt. X40CrMoV5-1 steel is particularly suitable for processing corrosive engineering plastics, ensuring surface quality and dimensional stability of the product.

X40CrMoV5-1 STEEL CHARACTERISTICS

X40CrMoV5-1 steel is a high-quality hot work die steel known for its excellent high-temperature stability and comprehensive mechanical properties. X40CrMoV5-1 steel is widely used in high-temperature working conditions such as die-casting molds and hot forging molds, and occupies an important position in the European industrial system.

X40CrMoV5-1 steel adopts an alloy ratio of 5% chromium, 1.3% molybdenum, and 1% vanadium to form a stable carbide network. This alloy design allows it to maintain a working hardness of over 40HRC even in a high temperature environment of 600 ℃, significantly better than ordinary mold steel. The high temperature strength retention rate can reach over 85%, which is particularly suitable for continuous high temperature operation scenarios such as aluminum alloy die-casting.

The heat treatment process of X40CrMoV5-1 steel is crucial for its performance. It is recommended to use oil quenching at 1020-1050 ℃ and secondary tempering at 580-630 ℃ to achieve the best balance between hardness and toughness. After standardized heat treatment, the material hardness can reach 50-54HRC, and the impact toughness is maintained at the level of 25-30J/cm ², meeting the requirements of most hot work molds.

In terms of processing performance, X40CrMoV5-1 steel exhibits good machinability in the annealed state. The steel produced by electroslag remelting (ESR) process has higher purity, and the surface roughness after polishing can reach Ra0.05 μ m or less. The pre hardened version (28-32HRC) can be directly precision machined, greatly reducing the mold manufacturing cycle.

In terms of thermal fatigue resistance, X40CrMoV5-1 steel has significantly improved its ability to resist thermal crack propagation by optimizing carbide distribution. Practical application data shows that the service life of aluminum die-casting molds is 30-40% longer than that of ordinary H13 steel, effectively reducing mold maintenance frequency and production downtime.

The corrosion resistance of X40CrMoV5-1 steel is due to the protective effect of 5% chromium content, which enables it to resist the erosion of molten metal and cooling medium. However, surface treatment is still necessary to enhance protection in sulfur-containing or high chlorine environments. After nitriding treatment, the surface hardness and wear resistance can be further improved, and the HV can reach over 1200.