SKD61 Hot Work Tool Steel

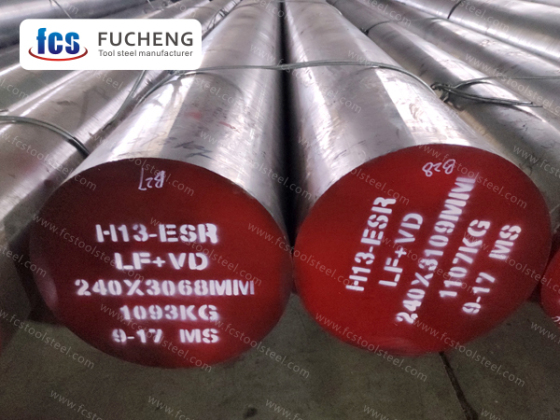

As a Japanese JIS standard hot work die steel, SKD61 steel's core highlights include excellent high-temperature performance, outstanding wear resistance and toughness, good processing performance, corrosion resistance, and wide applicability. SKD61 steel ensures material purity through vacuum degassing and electric slag remelting processes, combined with a heat treatment process of 1020-1050 ℃ quenching+550-680 ℃ triple tempering, which increases mold life by more than 50%.

- Fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

SKD61 TOOL STEEL

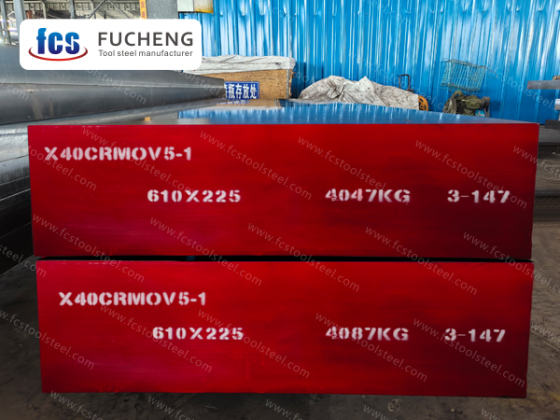

| Smelting and Manufacture Method: | LF+VD+ESR+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤235 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

SKD61 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| JIS | SKD61 | 0.35~0.42 | 0.80~1.20 | 0.25~0.50 | 4.80~5.50 | 1.00~1.50 | 0.80~1.15 |

| ASTM | H13 | 0.32~0.45 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.75 | 0.80~1.20 |

| DIN/W-Nr. | X40CrMoV5-1/1.2344 | 0.35~0.42 | 0.90~1.20 | 0.30~0.50 | 4.80~5.50 | 1.20~1.50 | 0.90~1.15 |

APPLICATION

SKD61 steel is suitable for hot work, aluminum, magnesium, zinc, copper alloy die-casting die, slotting cutter, scissors and hot forging action, plastic mold, hot work reamer, rolling cutter, general hot work forging die, hot bolt die, hot room tools, etc.

SKD61 STEEL CHARACTERISTICS

SKD61 steel is a type of hot work mold steel, which is the most widely used hot work mold steel. It is a hot alloy steel with good strength, toughness, and heat resistance balance. In recent years, with the development of isotropic products, it has increasingly developed towards high toughness and other aspects, which can make the mold life longer, performance more stable, and easy to process, with small heat treatment deformation.

The characteristics of SKD61 steel mainly include the following: firstly, it has high-temperature strength and toughness, good wear resistance, and is easy to cut. Secondly, SKD61 steel is the most widely used mold material for aluminum and zinc die-casting, suitable for hot work, aluminum, magnesium, zinc, copper alloy die-casting molds, groove cutters, scissors, and hot forging actions, plastic molds, hot working reamers, rolling knives, general hot working forging molds, hot bolt molds, and various tools during hot working. In addition, it also has the characteristics of pure steel treated with vacuum degassing and refining, good cutting performance after spheroidizing annealing and softening treatment, special addition of strengthening elements vanadium and molybdenum, and extremely excellent wear resistance. Finally, it undergoes quenching and tempering treatment to obtain a martensitic structure with fine and moderate grain size, which is basically distributed with small carbonized substances. It has good comprehensive mechanical properties and good hardenability, making it more suitable for manufacturing molds with large sizes and complex shapes.

In practical applications, the application range of SKD61 steel is very wide. Due to its good high-temperature strength and toughness, it is often used to manufacture molds that need to withstand higher temperatures and pressures. For example, SKD61 steel is widely used in mold materials for aluminum and zinc die-casting. In addition, SKD61 steel is widely used in manufacturing fields such as plastic molds, hot forging forming molds, and cold stamping molds. In these fields, the advantages of high strength, high wear resistance, and high toughness exhibited by SKD61 steel have been fully utilized.

In addition, SKD61 steel is also widely used in the field of electronics and electrical appliances. For example, SKD61 steel is used in the manufacturing process of switch housings, electric iron soleplates, etc. These products all need to withstand high temperatures and pressures, so the requirements for mold materials are also very high. The high-temperature strength and wear resistance of SKD61 steel can ensure the stability and safety of these products during use.

Overall, SKD61 steel is a mold steel with good toughness and high-temperature fatigue resistance, as well as the ability to withstand temperature fusion, suitable for long-term operation at high temperatures. At the same time, it also has good cutting performance and polishing performance. These characteristics make SKD61 steel one of the most widely used hot work mold steels at present.