1.2344 Hot Work Tool Steel

1.2344 steel, as a high-quality hot work die steel, has excellent comprehensive performance. It is processed by electric slag remelting to obtain a highly pure and uniformly structured material, exhibiting excellent high-temperature strength, wear resistance, and thermal fatigue resistance. 1.2344 steel can maintain stable performance in high temperature environments above 600 ℃, making it particularly suitable for harsh working conditions such as die-casting and hot forging; 1.2344 steel has good toughness and ductility, which can effectively resist impact loads. Its excellent processing performance can achieve mirror polishing effect, and its outstanding corrosion resistance makes 1.2344 steel an ideal material for manufacturing high-end die-casting molds, plastic molds, and hot work molds. It is widely used in fields such as automotive, electronics, and aerospace.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

1.2344 TOOL STEEL

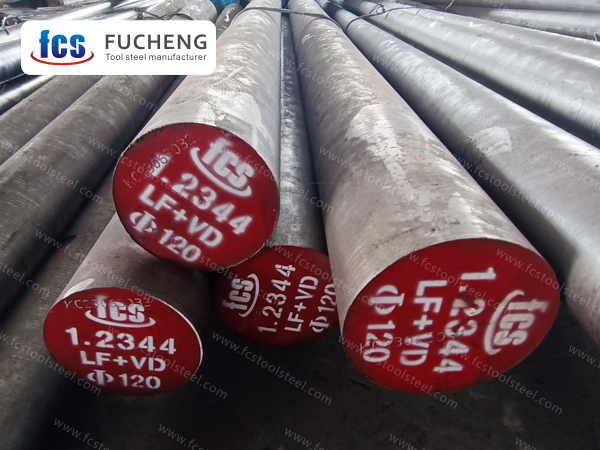

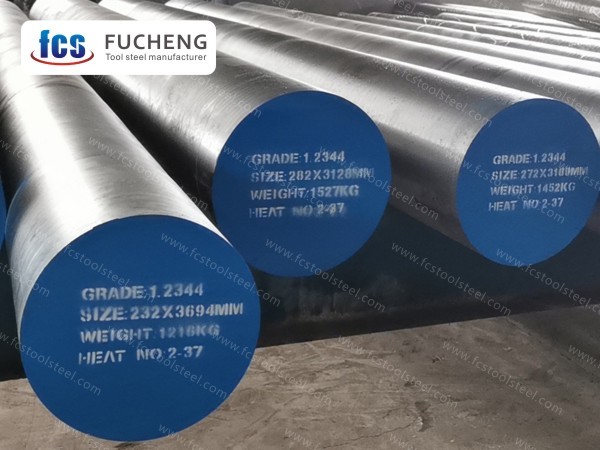

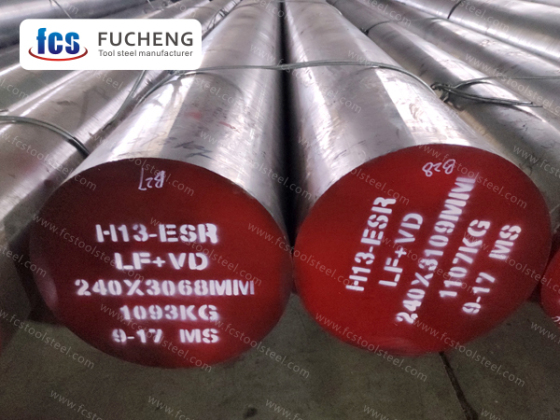

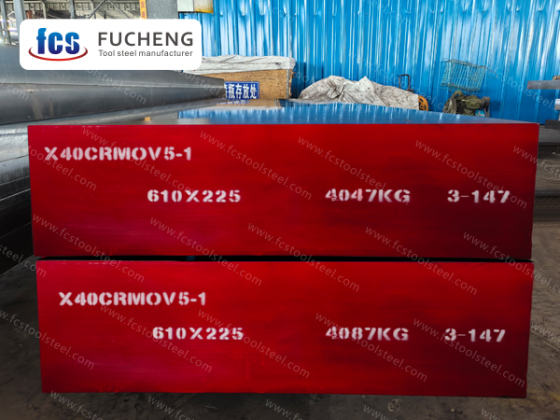

| Smelting and Manufacture Method: | LF+VD+ESR+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤235 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

1.2344 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| DIN/W-Nr. | X40CrMoV5-1/1.2344 | 0.35~0.42 | 0.90~1.20 | 0.30~0.50 | 4.80~5.50 | 1.20~1.50 | 0.90~1.15 |

| ASTM | H13 | 0.32~0.45 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.75 | 0.80~1.20 |

| JIS | SKD61 | 0.35~0.42 | 0.80~1.20 | 0.25~0.50 | 4.80~5.50 | 1.00~1.50 | 0.80~1.15 |

APPLICATION

1.2344 steel occupies a dominant position in the field of aluminum zinc die-casting molds. Its optimization can withstand repeated flushing of molten metal at 700 ℃, and its thermal fatigue resistance is improved by more than 30% compared to ordinary mold steel. It is particularly suitable for the production of complex die-casting parts such as automotive engine cylinder blocks. 1.2344 steel undergoes isotropic treatment to achieve uniform toughness in all directions, significantly reducing the risk of mold cracking.

1.2344 steel performs well in the field of plastic molds, especially suitable for injection molding of fiberglass reinforced engineering plastics. After tempering at 530-560 ℃, it has both wear resistance and polishing properties, with a surface roughness of Ra0.05 μ m. The 1.2-1.5% molybdenum content significantly reduces the wear rate of glass fibers. After nitriding treatment, the surface hardness of 1.2344 steel reaches 800-1000HV, and the friction coefficient drops below 0.3.

1.2344 steel is also widely used in the manufacturing of high-temperature cutting tools, such as continuous casting billet cutting guide wheels, steel billet hot cutting machine blades, etc. At 800 ℃, it still maintains a hardness of HRC40 or above, and the silicon content (0.8-1.2%) synergistically improves the red hardness with vanadium carbides. 1.2344 steel can accurately control the thickness of the infiltration layer by 0.1-0.3mm through ion nitriding, extending the tool life by 3-5 times.

1.2344 steel heat treatment

Forging, annealing, quenching, tempering

1050-850 ℃ 820-840 ℃ 1020-1050 ℃ 520-700 ℃

Purity: According to ASTME45 method A, A sulfide ≤ 0.5, B oxide, C silicate, and D spherical oxide ≤ 1 each, or DIN50602-K1 ≤ 10, or according to customer requirements.

Isothermal annealing specification

Annealing temperature (85010) C, insulation for 2 hours, cooling to (72010) ℃ with furnace, insulation for 4 hours, furnace cooling to below 500C, air cooling after discharge, hardness ≤ 229HBW.

High temperature tempering specification

Tempering temperature (73010) C, insulation for 2 hours, furnace cooling ≤ 500C, outlet air cooling.

Quenching and tempering specifications

Quenching temperature 850~880 ℃, oil cooled, hardness 50~52HRC; Tempering temperature 580-640C, outlet air cooling, hardness 28-36HRC

Specification for pre hardening treatment

Heating temperature 860-900C, oil cooled, tempering temperature 570-70OC, air cooled, tempering hardness 28-35HRC.

1.2344 Steel Physical Properties

(1) Density: 7.31g/cm.

(2) Linear expansion coefficient:

Temperature 18-100 ℃ 18-200C 18-300C 18-400C 18-500 ℃ 18-600 ℃ 18-600 ℃

Linear expansion coefficient 11.910K 12.2010K 12.5010K 12.8110K 13.1110K 13.4110K 13.7110K

(3) Elastic modulus: (20C) 212000MPa, shear modulus (room temperature) 825000MPa, Poisson's ratio 0.288

(4) Thermal conductivity:

Temperature 20 ℃ 100 ℃ 200C 300C 400C

Thermal conductivity 36.0 [W/(mK)] 33.4 [W/(mK)] 31.4 [W/(mK)] 30.1 [W/(mK)] 29.3 [W/(mK)]

Application status: 30-56HRC.

Pre hard hardness ≤ 28HRC; Annealed state, hardness ≤ 22HRC