- Home

- >

- Products

- >

- X37CrMoV5-1 Steel

- >

X37CrMoV5-1 Steel

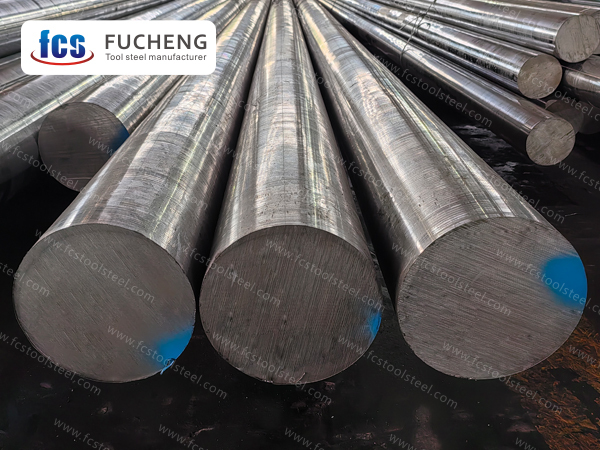

X3CrMoV5-1 steel, as a pre hardened hot work die steel, has the core advantage of balancing high temperature strength, wear resistance, and thermal fatigue resistance, making it particularly suitable for high temperature and high pressure scenarios such as die-casting/forging molds.

- Fucheng Steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

- Download

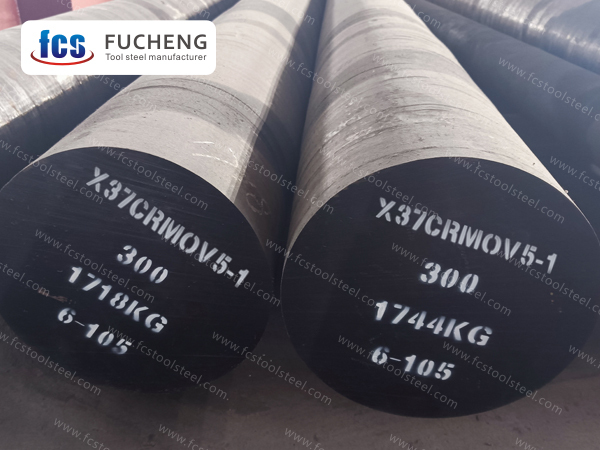

X37CrMoV5-1 TOOL STEEL

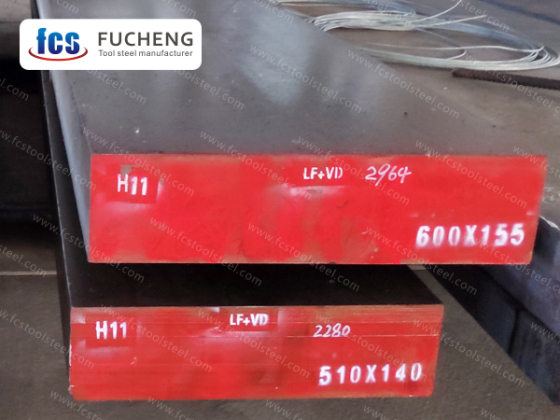

| Smelting and Manufacture Method: | LF+VD+ESR+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤229 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

X37CrMoV5-1 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| DIN/W-Nr. | X37CrMoV5-1/1.2343 | 0.33~0.41 | 0.80~1.20 | 0.25~0.50 | 4.80~5.50 | 1.10~1.50 | 0.30~0.50 |

| ASTM | H11 | 0.33~0.43 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.60 | 0.30~0.60 |

| JIS | SKD6 | 0.32~0.42 | 0.80~1.20 | ≤0.50 | 4.50~5.50 | 1.00~1.50 | 0.30~0.50 |

APPLICATION

X3CrMoV5-1 steel is a high-performance hot work die steel mainly used for die-casting molds, plastic molds, and hot forging tools. X37CrMoV5-1 steel is high temperature resistant and fatigue resistant, suitable for manufacturing precision molds for high-end industries such as automobiles and aviation.

X37CrMoV5-1 Steel Characteristics

X3CrMoV5-1 steel is a high-performance hot work die steel widely used in the industrial field due to its excellent heat resistance, wear resistance, and toughness.

X37CrMoV5-1 steel belongs to chromium molybdenum vanadium alloy steel, which has high hardenability and good high-temperature strength. The combined action of chromium, molybdenum, and vanadium elements in its chemical composition endows X3CrMoV5-1 steel material with excellent heat fatigue resistance and tempering softening resistance, and can maintain stable mechanical properties below 600 ℃.

The typical heat treatment process for X37CrMoV5-1 steel includes austenitization at 1020-1060 ℃ followed by oil quenching, and then tempering at 450-650 ℃. By reasonable heat treatment, a hardness of 53-56 HRC can be obtained while maintaining good toughness.

In the heat-treated state, the tensile strength of X3CrMoV5-1 can reach over 1300 MPa, with high yield strength and moderate elongation. Its high-temperature yield strength is particularly outstanding, and it can still maintain a high level of strength at 500 ℃.

X37CrMoV5-1 steel has good machinability and can be machined by turning, milling, and other mechanical processes. Electric discharge machining has excellent performance and is suitable for manufacturing molds with complex cavities. Good polishing performance can achieve a high smoothness of the mold surface.

X37CrMoV5-1 steel material has become an indispensable high-end material in modern mold manufacturing due to its comprehensive performance, and is widely used in high-end manufacturing fields such as automobiles, aerospace, electronics, etc.