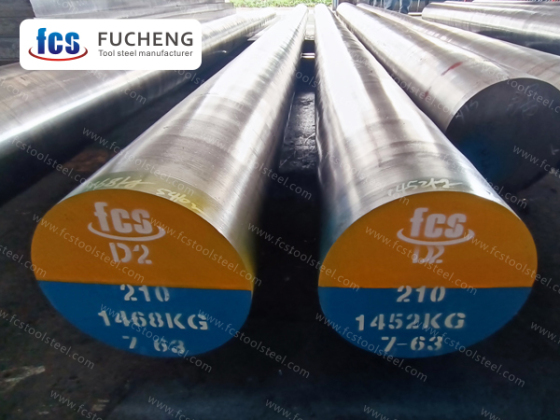

D2 Tool Steel | 1.2379 | X155CrVMo12-1 | SKD11

As a benchmark for high carbon and high chromium cold work die steel, D2 steel's core highlight lies in the precise ratio of 12% chromium content and 1.5% carbon to form a large number of hard carbides. It maintains an ultra-high hardness of 60-62HRC while also having better wear resistance than ordinary tool steel (5-8 times that of ordinary steel). After appropriate heat treatment, D2 steel can significantly improve its anti cracking performance, especially suitable for high-strength wear scenarios such as precision punching dies and shear cutting tools. D2 steel, known as "semi stainless steel", also forms a passive film on its surface to delay corrosion, becoming a classic choice for balancing performance and cost in the industrial field.

- Fucheng steel

- China

- 1 month

- 2,000 Tons/ Month

- Information

- Video

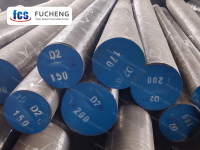

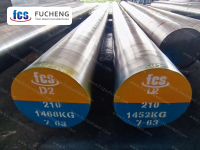

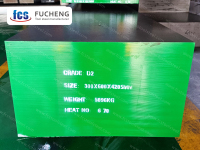

D2 TOOL STEEL

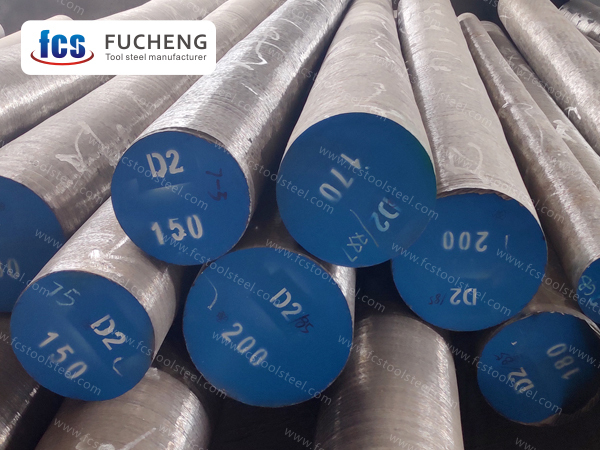

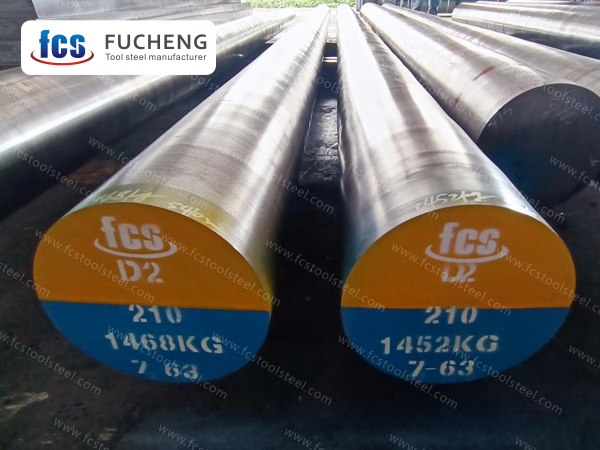

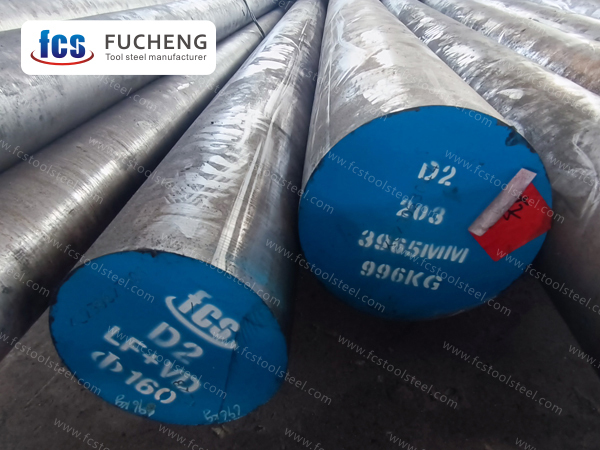

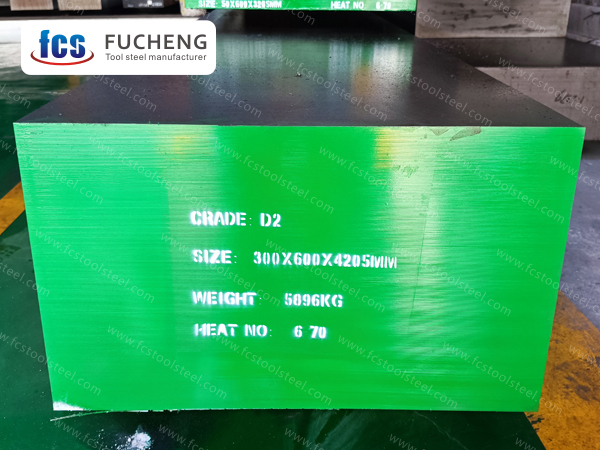

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

D2 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ASTM | D2 | 1.40~1.60 | ≤0.60 | 0.10~0.60 | 11.00~13.00 | 0.70~1.20 | 0.50~1.10 |

| DIN/W-Nr. | X155CrVMo12-1/1.2379 | 1.45~1.60 | ≤0.60 | 0.20~0.60 | 11.00~13.00 | 0.70~1.00 | 0.70~1.00 |

| JIS | SKD11 | 1.40~1.60 | ≤0.40 | ≤0.60 | 11.00~13.00 | 0.80~1.20 | 0.20~0.50 |

APPLICATION

D2 tool steel is suitable for tool steel with complex deformation, all kinds of cold stamping dies with high wear resistance and long life, cold shear blades, and thread rolling plates; Cold extrusion forming, stretching film, beer stainless steel sheet and balance cutting die of high hardness materials, etc

D2 STEEL CHARACTERISTICS

As a representative of high carbon and high chromium alloy tool steel, D2 steel's core characteristics stem from its unique chemical composition design. The ratio of carbon content 1.4% -1.6% to chromium content 11% -13% in D2 steel forms a large number of hard chromium carbide particles, which is the microscopic basis of its properties.

The most prominent advantage of D2 steel is its extreme wear resistance, with a hardness of 58-62HRC after heat treatment. This characteristic makes D2 steel excellent in the field of cold work molds, especially suitable for withstanding high-strength stamping wear of metal sheets.

D2 steel has excellent air cooling hardening characteristics, and high hardness can be obtained by air cooling. The self hardening ability of D2 steel significantly reduces the risk of heat treatment deformation, which is crucial for precision mold manufacturing and can maintain dimensional stability within ± 0.05mm.

Although classified as air hardened steel, D2 still retains moderate toughness. Through graded quenching process control, the impact toughness of D2 steel can reach 20-30J/cm ², making it a material with good balance among wear-resistant steels.

D2 steel exhibits corrosion resistance between ordinary carbon steel and stainless steel. The passivation film formed by the chromium element in D2 steel gives it basic rust prevention ability, but surface protection is still required for long-term exposure to humid environments.

The heat treatment process has a significant impact on the properties of D2 steel. The recommended process route is oil quenching at 1020-1040 ℃ and tempering at 180-220 ℃. D2 steel can achieve the optimal ratio of hardness and toughness, with a residual austenite conversion rate exceeding 95%.

Attention should be paid to the selection of cutting tools when machining D2 steel. It is recommended to use hard alloy or CBN cutting tools, with a cutting speed controlled at 80-120m/min and sufficient cooling to avoid work hardening.