- Home

- >

- Products

- >

- 1.2379 Tool Steel

- >

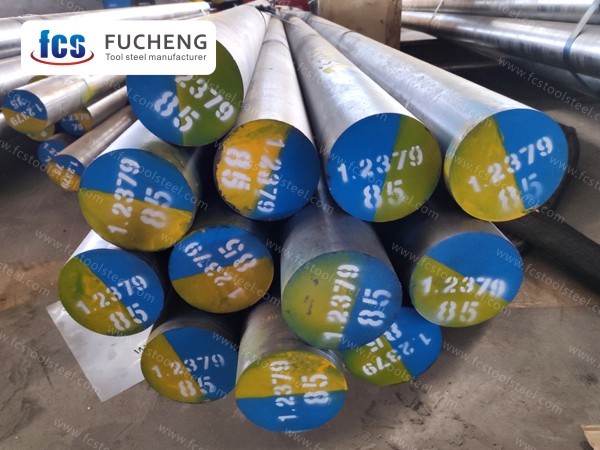

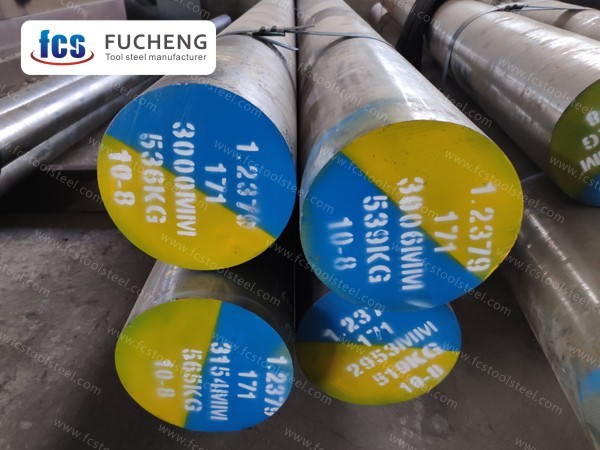

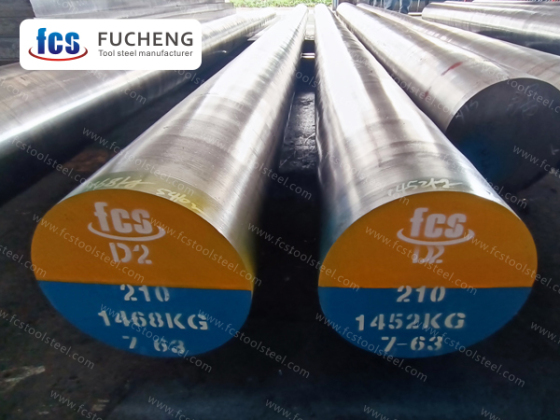

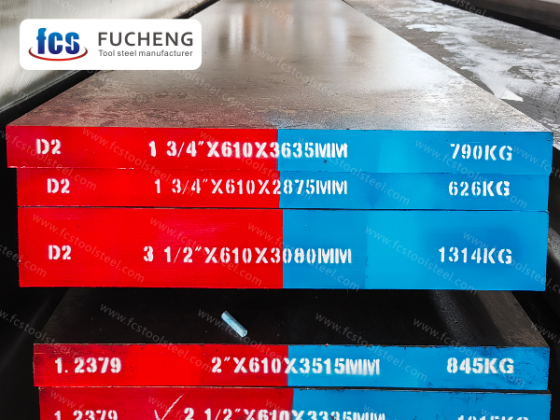

1.2379 Tool Steel

1.2379 steel is mainly used for high wear-resistant cold work molds (such as stamping molds, shearing knives), precision plastic molds (especially fiberglass reinforced injection molds), and rolling tools, and is suitable for large-scale production scenarios in industries such as automotive and electronics.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

1.2379 TOOL STEEL / x153crmov12 steel

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

1.2379 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| DIN/W-Nr. | X153CrMo12/1.2379 | 1.45~1.60 | ≤0.60 | 0.10~0.40 | 11.00~13.00 | 0.70~1.00 | 0.70~1.00 |

| ASTM | D2 | 1.40~1.60 | ≤0.60 | 0.10~0.60 | 11.00~13.00 | 0.70~1.20 | 0.70~1.10 |

| JIS | SKD11 | 1.40~1.60 | ≤0.40 | ≤0.40 | 11.00~13.00 | 0.80~1.20 | 0.20~0.50 |

APPLICATION

1.2379 steel is mainly used in the manufacturing of precision cold work molds and wear-resistant tools, such as punching dies, cutting tools, injection molds, etc. It is particularly suitable for high-precision sheet metal stamping and glass fiber reinforced plastic molding. Its high hardness (HRC 60-62) and wear resistance significantly improve tool life.

1.2379 steel is widely used in the industrial field for stamping automotive parts, processing electronic connectors, and aerospace fixtures. It can withstand high-strength wear and tear in large-scale production and has a lifespan of 3-5 times that of ordinary steel.

1.2379 STEEL CHARACTERISTICS

1.2379 steel is a high carbon and high chromium cold work die steel, known for its excellent wear resistance and high hardness. It is widely used in the fields of precision stamping, cold forging, and plastic molding die manufacturing.

In terms of chemical composition, the carbon content of 1.2379 steel ensures high hardness, while chromium forms a large amount of carbides to enhance wear resistance. The addition of molybdenum and vanadium significantly improves the toughness and resistance to tempering softening of the material. The special alloy design of 1.2379 steel allows it to maintain high hardness while still having good impact resistance, making it particularly suitable for high load conditions.

The heat treatment process is crucial for the performance of 1.2379 steel. It is recommended to use oil quenching at 1020-1040 ℃ and low-temperature tempering at 180-220 ℃ to achieve high hardness of HRC62-64; If toughness needs to be taken into account, high-temperature tempering at 500-530 ℃ can be chosen. It is worth noting that 1.2379 steel has extremely low deformation during quenching and excellent dimensional stability.

In terms of mechanical properties, 1.2379 steel exhibits excellent wear resistance after quenching and tempering, with a wear resistance level 3-5 times that of ordinary tool steel. At the same time, the compressive strength exceeds 2500MPa and can withstand extremely high local pressure without plastic deformation, making 1.2379 steel an ideal choice for heavy-duty stamping dies.

In terms of processing performance, the annealed 1.2379 steel has a hardness of about 220HB and good machinability. However, it is important to strictly control the temperature during grinding to avoid surface softening caused by overheating. After electrical discharge machining, stress relief tempering must be carried out to eliminate the influence of white layer on the machined surface.

1.2379 steel is mainly used in three major fields in industrial applications: precision punching molds such as automotive parts stamping molds; High wear-resistant plastic injection molds, especially fiberglass reinforced material molding molds; And various cold forming tools such as rolling dies and cutting tools.

1.2379 steel has excellent resistance to tempering softening, and its hardness remains stable when tempered below 500 ℃. 1.2379 steel has excellent hardenability, and large section workpieces can also obtain uniform hardness distribution, which provides convenience for the manufacturing of large molds.