- Home

- >

- Products

- >

- D3 Tool Steel

- >

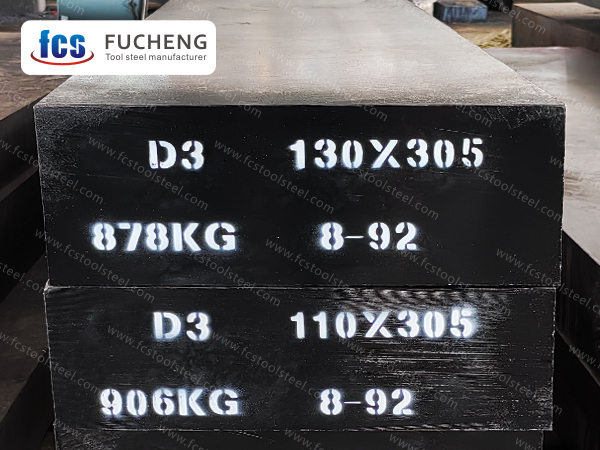

D3 Tool Steel

D3 steel is suitable for concave and convex dies, inserts, stretching and blanking dies, wire rollers, punches, scissors, etc. with complex shapes.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

D3 TOOL STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

D3 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||

| C | Si | Mn | Cr | ||

| ASTM | D3 | 2.0~2.35 | 0.10~0.60 | 0.20~0.60 | 11.0~13.5 |

| DIN/W-Nr. | X153CrMo12/1.2080 | 1.9~2.20 | 0.10~0.40 | 0.15~0.45 | 11.0~12.0 |

| JIS | SKD1 | 1.9~2.20 | 0.10~0.60 | 0.20~0.60 | 11.0~13.0 |

APPLICATION

D3 steel is mainly used to manufacture high wear-resistant and high-precision cold work molds, especially suitable for high load working conditions such as punching dies, deep drawing dies, and cold extrusion dies. The excellent wear resistance of D3 steel makes it outstanding in the stamping processing of hard materials such as silicon steel sheets and stainless steel plates.

D3 steel is also commonly used to make precision measuring tools (such as block gauges, gauges), cutting tools (such as shear blades), and wear-resistant inserts for plastic molding molds.

D3 STEEL CHARACTERISTICS

As a high carbon and high chromium cold work die steel, the characteristics of D3 steel can be comprehensively analyzed from material composition, mechanical properties to application performance. D3 steel occupies an important position in the field of mold manufacturing due to its unique alloy ratio and heat treatment response.

The chemical composition design of D3 steel highlights its wear-resistant orientation, with a carbon content of 2.00-2.35% combined with 12% chromium element, forming a large amount of M7C3 type carbides. The microstructure of D3 steel endows the material with extremely high hardness potential, reaching 60-62HRC after quenching, with a carbide volume fraction exceeding 15%, which is a leading level among similar steel grades.

The heat treatment process characteristics of D3 steel are characterized by a narrow quenching window (940-980 ℃), which requires oil quenching or graded quenching to avoid cracking. The secondary hardening effect of D3 steel is significant, and the hardness peaks after tempering at 500 ℃. However, if it exceeds 550 ℃, the performance will sharply decrease due to carbide aggregation, which requires precise process control.

The wear resistance can be regarded as the most outstanding advantage of D3 steel, and its service life can reach 1.8 times that of SKD11 steel in aluminum plate punching tests. Its wear mechanism is mainly carbide peeling, and its surface roughness maintenance ability is excellent. D3 steel is particularly suitable for harsh working conditions such as precision stamping dies and drawing dies.

D3 steel exhibits excellent compressive strength, reaching over 2500MPa at room temperature. However, the impact toughness is relatively weak (about 15J/cm ² for samples without notches), and caution should be exercised when applying it to mold parts with stress concentration. D3 steel is usually recommended for static or mild impact load scenarios.

In terms of dimensional stability, the quenching deformation rate of D3 steel is about 0.15% -0.25%, which is lower than most alloy tool steels. D3 steel can reduce subsequent processing stress through preheating treatment (600 ℃ × 2h), and the final dimensional deviation of precision molds can be controlled within ± 0.02mm/m.

The machining performance of D3 steel shows polarization: the annealed state (≤ 255HB) has good turning performance, but the quenched state requires the use of CBN cutting tools. White layer is prone to occur during electrical discharge machining of D3 steel, which needs to be eliminated by aging treatment at 160-180 ℃.

D3 steel has better corrosion resistance than ordinary tool steel, and its 12% chromium content allows it to form a passive film in humid environments. However, compared to stainless steel, long-term exposure to coolant still requires surface treatment. It is recommended to use chrome plating or PVD coating to enhance protection.