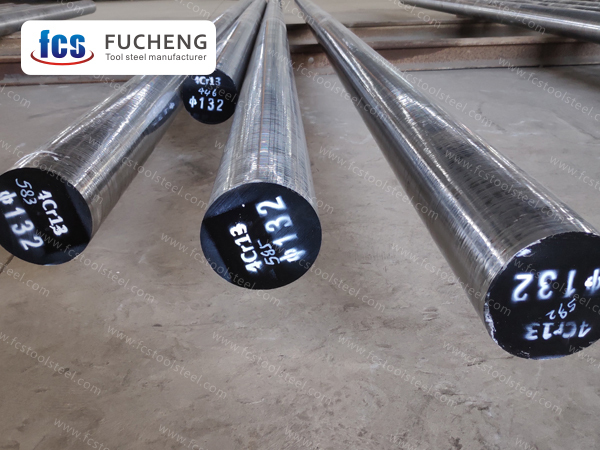

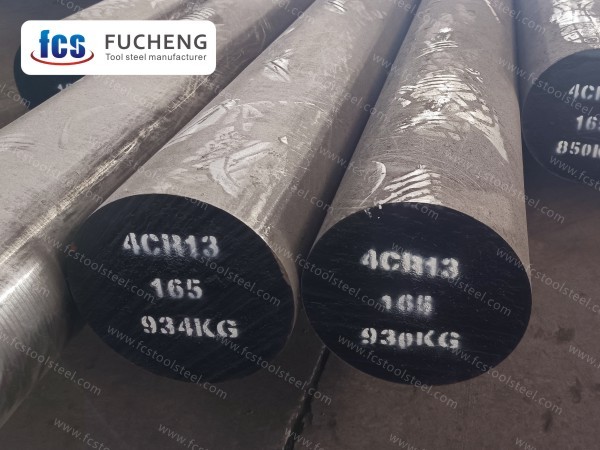

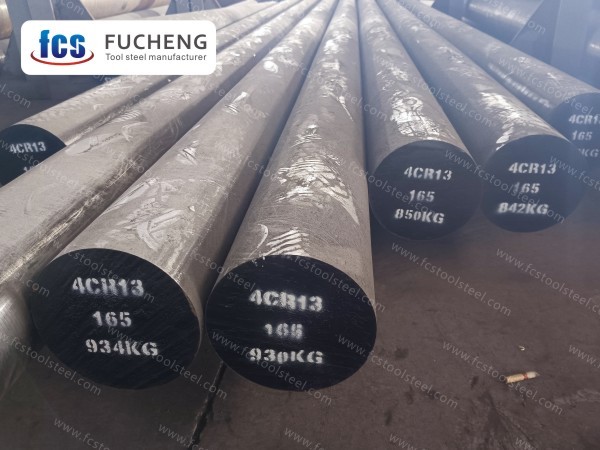

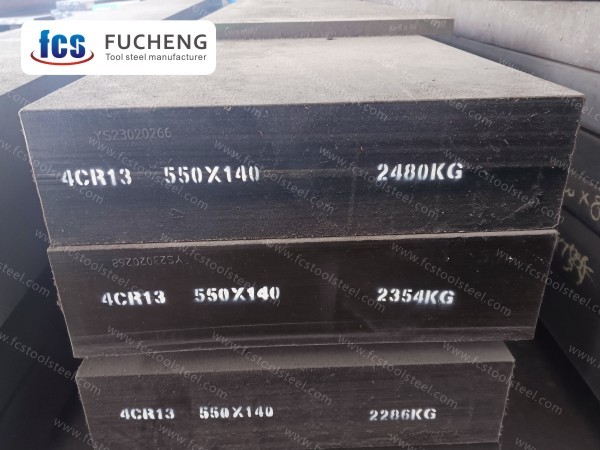

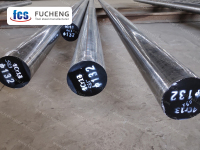

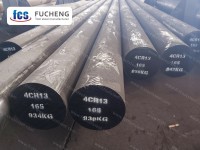

FCS 4Cr13 Plastic Mould Steel

The biggest advantage of 4Cr13 steel is its high hardness, good wear resistance, and good corrosion resistance. 4Cr13 steel is particularly suitable for manufacturing cutting tools, medical devices, molds, and durable parts that require rust prevention.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

4Cr13 PLASTIC MOULD STEEL

| Brand | FCS |

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤225 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

4Cr13 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||

| C | Si | Mn | Cr | ||

| GB | 4Cr13 | 0.35~0.45 | ≤0.60 | ≤0.80 | 12.0~14.0 |

| ASTM | 420SS | 0.30~0.40 | ≤1.00 | ≤1.25 | 12.0~14.0 |

| DIN/W-Nr. | X42Cr13/1.2083 | 0.38~0.45 | ≤1.00 | ≤1.00 | 12.5~13.5 |

| JIS | SUS420J2 | 0.26~0.40 | ≤1.00 | ≤1.00 | 12.0~14.0 |

APPLICATION

4Cr13 steel is suitable for high mirror surface and high precision injection mold core and cavity. Or as hot oil pump, valve plate, valve bearing, medical device, spring and other parts with corrosion resistance and wear resistance.

4Cr13 stainless steel characteristics

4Cr13 steel is a martensitic type of stainless steel that has high hardness and wear resistance after quenching, good corrosion resistance, and is suitable for manufacturing plastic molds that can withstand high loads, wear resistance, and corrosive media, as well as transparent plastic product molds.

4Cr13 steel is widely used in various fields due to its high hardness, wear resistance, corrosion resistance, and other characteristics. For example, in the industrial field, it is suitable for discharge and grinding processing, and can be used for high-precision injection mold core cavity with high mirror surface. After heat treatment, it has high hardness and toughness, and can also be used for stamping mold accessories, templates, etc. In the civilian field, it can be used to make tableware knives, outdoor knives, etc.

However, although 4Cr13 steel has many advantages, it also has some limitations. Firstly, although it has good corrosion resistance, its corrosion resistance may decrease in special environments such as strong acids and alkalis. Therefore, in certain special application scenarios, it may be necessary to choose other types of stainless steel materials. Secondly, the cutting performance of 4Cr13 steel is poor, and special cutting tools and techniques are required for effective machining. In addition, due to its high hardness, special care is required during heat treatment to prevent the generation of cracks and other heat treatment defects.

During the use of 4Cr13 steel, it is also necessary to pay attention to some maintenance and upkeep issues. Firstly, regular cleaning and maintenance should be carried out to prevent rust and other surface contamination. Secondly, during use, severe impact and excessive pressure should be avoided to prevent cracks and other damage. Finally, if any abnormal wear or damage is found, it should be promptly inspected and repaired to prevent further deterioration of the problem.

Overall, 4Cr13 steel is a high-performance stainless steel material with good hardness, wear resistance, and corrosion resistance, widely used in various industrial and civil fields. However, due to its certain limitations and the need for special handling and maintenance requirements, reasonable selection and use need to be made based on the actual situation during the use process.