- Home

- >

- Products

- >

- 38CrMoV5-3 Steel

- >

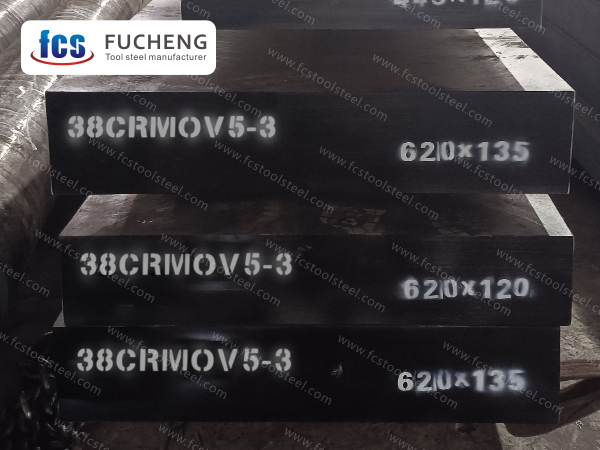

38CrMoV5-3 Steel

38CrMoV5-3 steel has high high temperature strength, high temperature wear resistance and crack propagation resistance.

38CrMoV5-3 steel is usually used for hot forging dies with high service life requirements, aluminum and zinc die casting dies. Aluminum alloy, copper alloy extrusion die, complex extrusion die.

- Fucheng

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

- Download

38CrMoV5-3 STEEL

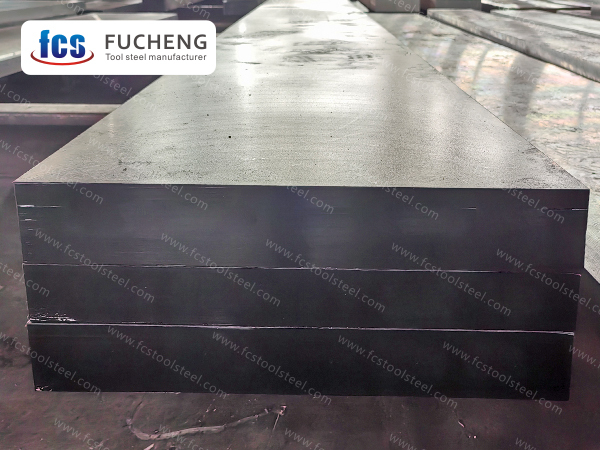

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤235 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

38CrMoV5-3 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| DIN/W-Nr. | 38CrMoV5-3/1.2367 | 0.35~0.40 | 0.30~0.50 | 0.30~0.50 | 4.80~5.20 | 2.70~3.20 | 0.40~0.60 |

APPLICATION

38CrMoV5-3 steel occupies a dominant position in the field of die-casting molds, especially suitable for die-casting of light metals such as aluminum alloys and magnesium alloys. Its excellent thermal fatigue resistance can increase the mold life by more than 30%. The Cr7C3 carbide network formed in 38CrMoV5-3 steel at high temperatures can effectively resist the erosion of molten metal while maintaining sufficient toughness to prevent cracking.

38CrMoV5-3 steel hot forging die has outstanding performance in application, especially suitable for hot forging processing of difficult to deform materials such as titanium alloy and high-strength steel. It can withstand instantaneous contact temperatures above 1200 ℃ without plastic deformation. The oxidation resistance provided by the 5% chromium content in 38CrMoV5-3 steel can reduce the formation of oxide scale on the mold surface.

When 38CrMoV5-3 steel is used as an extrusion die material, it exhibits excellent performance in the hot extrusion production of copper alloy pipes and aluminum profiles, with a continuous working temperature of up to 600 ℃ and stable hardness. The MC type carbide formed by vanadium element significantly enhances the anti-wear ability of the mold.

38CrMoV5-3 steel is particularly suitable for the molding of fiberglass reinforced engineering plastics in the field of plastic injection molds. Its high molybdenum content (2.7-3.2%) effectively resists the abrasion of fiberglass. After tempering at 530-560 ℃, the hardness can reach 48-52HRC, balancing wear resistance and demolding performance.

38CrMoV5-3 steel is also widely used in the manufacturing of hot cutting tools, such as steel billet hot cutting machine blades, continuous casting billet flame cutting guide wheels, etc. Its high temperature red hardness allows it to maintain a hardness of HRC40 or above at 800 ℃. Its optimized silicon content (0.3-0.5%) helps to improve high-temperature strength.

Special forming tools such as high-speed hammer forging dies and precision hot stamping heads are often made of 38CrMoV5-3 steel. Oil quenching at 1020-1050 ℃ combined with double tempering process can achieve the best combination of strength and toughness, with an impact value of 40-60J/cm ². The hardness deviation of large cross-section workpieces after processing does not exceed 2HRC, ensuring dimensional stability.

38CrMoV5-3 Steel Properties

38CrMoV5-3 mold steel is a high-quality hot work mold steel, which mainly includes high toughness, excellent high-temperature resistance, and excellent heat fatigue and wear resistance at high temperatures. This material is very suitable for manufacturing products with high quality requirements. Compared with traditional smelting steel, its isotropy is better, which means it has excellent toughness and plasticity in all directions. In addition, 38CrMoV5-3 mold steel also has good processability and heat treatment performance.

38CrMoV5-3 has high strength and wear resistance, making it an ideal mold steel material. However, attention should be paid to factors such as temperature, coolant, and surface quality during use, as these factors may affect the performance and service life of mold steel.

It is also worth mentioning that 38CrMoV5-3 is an electroslag remelting hot working steel, which makes its structure more uniform, material more purified, and has high isotropy, thereby possessing excellent high-temperature strength, high-temperature wear resistance, and crack propagation resistance. Therefore, in high demand application scenarios, such as those requiring heat resistance, high-temperature toughness, heat fatigue resistance, and wear resistance, 38CrMoV5-3 is an excellent choice.

Due to its superior mechanical properties and good heat treatment performance, 38CrMoV5-3 mold steel is widely used in the manufacturing of various mold products such as plastic molds and die-casting molds.