- Home

- >

- Products

- >

- 1.2367 Tool steel

- >

1.2367 Tool steel

The highlight of 1.2367 steel lies in its perfect performance balance: it maintains excellent toughness even at 62HRC ultra-high hardness, and its wear resistance life is more than three times that of ordinary mold steel; 1.2367 steel has excellent dimensional stability after deep cryogenic treatment (0.002mm/100mm), and maintains accuracy even after 2 million stamping cycles; The optimized heat treatment process of 1.2367 steel has increased processing efficiency by 40%, making it the preferred material for precision electronic molds.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

1.2367 STEEL

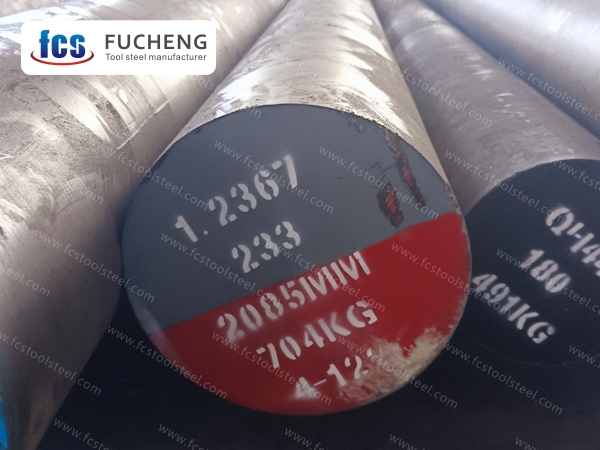

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤235 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

1.2367 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| DIN/W-Nr. | 38CrMoV5-3/1.2367 | 0.35~0.40 | 0.30~0.50 | 0.30~0.50 | 4.70~5.20 | 2.70~3.30 | 0.40~0.70 |

APPLICATION

1.2367 steel is mainly used to manufacture high demand hot work molds, such as aluminum alloy and magnesium alloy die-casting molds, as well as hot forging molds for automotive components such as engine cylinder blocks and gearbox housings. The excellent high temperature resistance (400-600 ℃) and thermal fatigue resistance of 1.2367 steel make it one of the preferred materials in the die-casting and hot forming industries.

In the field of plastic molds, 1.2367 steel is suitable for high-precision injection molds, especially for the molding of engineering plastics (such as PC, POM) and optical grade plastics (such as PMMA) that require long-term stable production. The high polishing and wear resistance of 1.2367 steel ensures that the mold maintains a smooth surface for a long time, reducing maintenance frequency.

1.2367 steel is also used to manufacture heavy machinery components such as hot shear cutting tools, high-temperature fixtures, and extruder screws. Thanks to its high toughness, impact resistance, and wear resistance, it can maintain stable performance under high temperature and high load conditions.

1.2367 STEEL CHARACTERISTICS

1.2367 steel, as a cold work die steel, occupies an important position in the field of precision molds due to its excellent comprehensive performance. 1.2367 steel achieves an excellent balance between wear resistance and toughness through precise chemical composition design.

The heat treatment characteristics of 1.2367 steel are characterized by a wide austenitization temperature window (980-1050 ℃). When using oil quenching process, a 100mm thick section can still ensure the uniformity of core hardness. The peak of secondary hardening of 1.2367 steel occurs in the tempering range of 500-520 ℃, at which point the impact toughness reaches the optimal balance.

The wear resistance of 1.2367 steel comes from a high volume fraction of carbides (about 15%). In the test of punching 0.5mm thick stainless steel plate, its service life can reach more than three times that of ordinary Cr12 steel. The specially designed carbide distribution of 1.2367 steel enables the material to simultaneously resist adhesive wear and abrasive wear.

The dimensional stability of 1.2367 steel is strengthened through cryogenic treatment process. The residual austenite content after treatment at -196 ℃ is less than 2%, and the dimensional change of precision molds during long-term use does not exceed 0.002mm/100mm. The characteristic of 1.2367 steel makes it the preferred material for optical lens molds.

The compressive strength of 1.2367 steel reaches 2800MPa level in the quenched and tempered state, and the elastic modulus remains at 210GPa. 1.2367 steel exhibits excellent resistance to plastic deformation under high load stamping conditions, making it particularly suitable for high-speed precision punching of stainless steel sheets.

The machining performance of 1.2367 steel is improved by optimizing the annealing process. After annealing with 1.2367 steel balls, the hardness is controlled within the range of 220-240HB. When using hard alloy cutting tools for processing, the tool life is increased by 40% compared to SKD11.

The environmental adaptability of 1.2367 steel is manifested in two aspects: corrosion resistance and high temperature oxidation resistance. The chromium containing carbide network of 1.2367 steel maintains stability in humid environments and does not produce significant oxide scale on the surface when subjected to short-term temperatures of 400 ℃.