- Home

- >

- Products

- >

- X12MΦ Tool Steel

- >

X12MΦ Tool Steel

X12MΦ steel is suitable for stamping dies, cold extrusion dies, wire rollers, wire rings, cold scissors, and precision measuring tools with complex shapes.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

X12MΦ STEEL

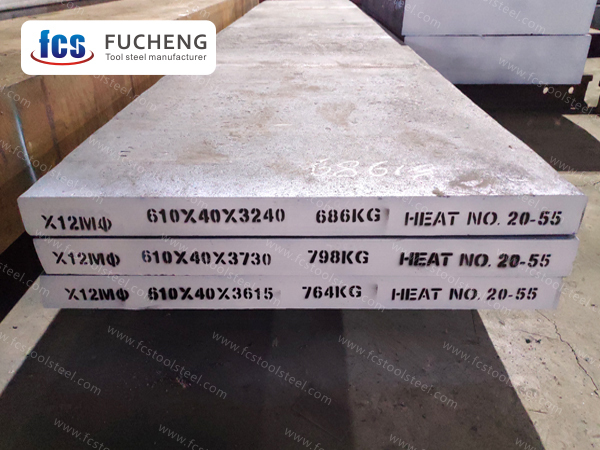

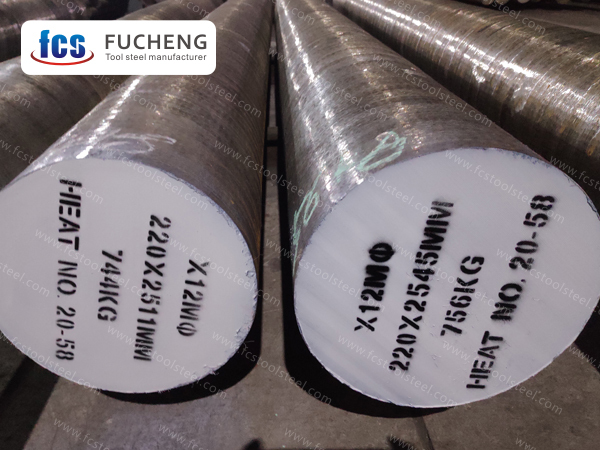

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

X12MΦ STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ГOСТ | X12MΦ | 1.45~1.65 | 0.10~0.40 | 0.15~0.45 | 11.00~12.50 | 0.40~0.60 | 0.15~0.30 |

| GB | Cr12MoV | 1.45~1.70 | ≤0.40 | ≤0.40 | 11.00~12.50 | 0.40~0.60 | 0.15~0.30 |

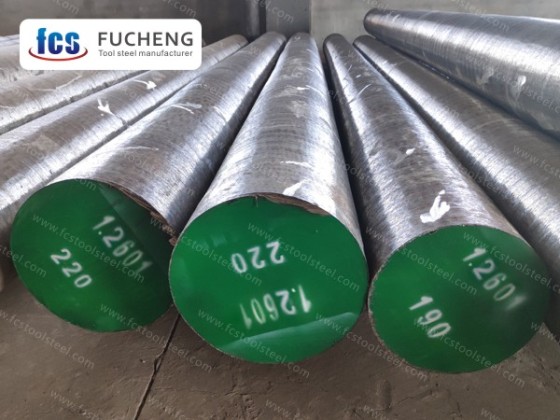

| DIN/W-Nr. | X165CrMoV12/1.2601 | 1.55~1.75 | 0.25~0.40 | 0.20~0.40 | 11.00~12.00 | 0.50~0.70 | 0.10~0.50 |

APPLICATION

X12MΦ steel is a high carbon and high chromium cold working die steel from Russia, mainly used for manufacturing precision punching dies, cold extrusion dies, and stretching dies. X12MΦ steel is also particularly suitable for large-scale production of automotive parts and other cold working scenarios that require high wear resistance and high precision.

X12MΦ STEEL CHARACTERISTICS

X12MΦ Steel is a high carbon and high chromium cold work mold steel, belonging to the martensitic steel. And it is widely used internationally, especially in the production of cold work molds. In addition, compared to Cr12 steel, X12MΦ The steel has a low carbon content and the addition of Mo and V improves the uneven distribution of carbides. Mo can reduce carbide segregation and improve hardenability, while V can refine grains and increase toughness.

X12MΦ Steel has high hardenability, and can be completely quenched below 400mm in cross-section. It can still maintain good hardness and wear resistance at 300-400 ℃. This type of steel has higher toughness than Cr12, less volume change during quenching, and high wear resistance. Therefore, X12M Φ Steel is an excellent mold material suitable for manufacturing various cold working molds, such as drawing molds, stamping molds, extrusion molds, etc.

X12MΦ steel has excellent performance, mainly due to its chemical composition and heat treatment process. Firstly, its carbon content is relatively high, reaching 1.4%, which endows the steel with high hardness and wear resistance. The chromium content of X12MΦ steel is also very high, reaching 12%, which helps to improve the hardenability and oxidation resistance of the steel. In addition, the addition of molybdenum and vanadium further enhances the strength and toughness of the steel.

The heat treatment process of X12MΦ steel is also crucial. Usually requires quenching and tempering treatment. Quenching is the process of heating steel to 820-840 ℃ and then rapidly cooling it to form a martensitic structure. X12MΦ steel has high hardness and wear resistance. Tempering is the process of heating steel to 500-650 ℃ after quenching, and then slowly cooling it to eliminate the stress and residual austenite generated during the quenching process. X12MΦ steel can improve its toughness and stability through tempering treatment.

X12MΦ Steel has shown excellent performance in practical applications. For example, in the field of automotive manufacturing, it can be used to manufacture various stamping molds, stretching molds, and extrusion molds. These molds need to withstand high temperature, high pressure, and high-speed impact loads, therefore requiring very high performance of steel. X12MΦ The high hardness, wear resistance, and hardenability of steel make it an ideal choice.

In addition, X12MΦ Steel can also be used to manufacture cutting tools, measuring tools, and other precision tools. In these applications, the dimensional accuracy and surface quality of steel are very important. X12MΦ The hardenability and heat treatment process of steel enable it to obtain very fine grain structures, thereby improving dimensional accuracy and surface quality.