- Home

- >

- Products

- >

- O2 Tool Steel

- >

O2 Tool Steel

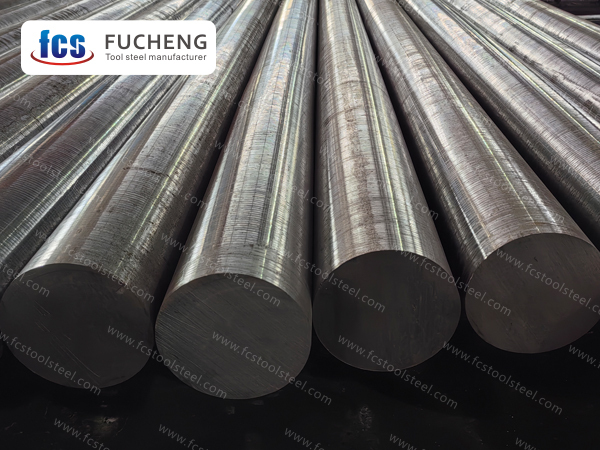

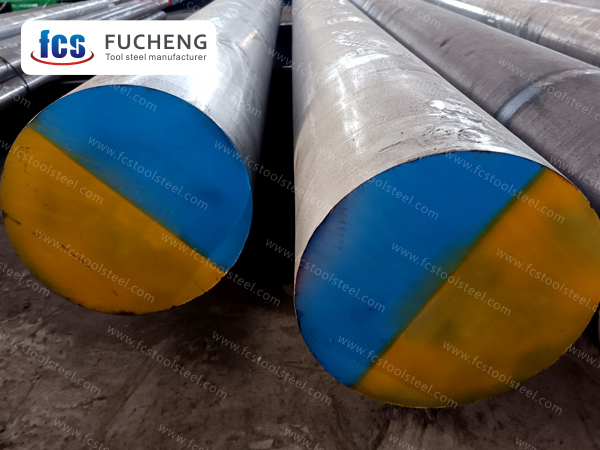

O2 steel, as a typical oil quenched die steel, exhibits superior hardness and wear resistance as its core characteristics. After standardized heat treatment, the hardness of O2 steel remains stable in the range of 58-62 HRC, with high carbon content (1.55-1.70%) forming uniform carbides with chromium elements, significantly improving the material's wear resistance, especially suitable for high load stamping scenarios. O2 steel is widely used in the manufacturing of small punching dies, gauges, and machine tool screws.

- fucheng steel

- China

- 1 month

- 2000 Tons/Month

- Information

- Video

O2 TOOL STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤212 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

O2 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ASTM | O2 | 0.85~0.95 | ≤0.50 | 1.40~1.80 | ≤0.50 | ≤0.30 | ≤0.30 |

| DIN/W-Nr. | 90MnCrV8/1.2842 | 0.85~0.95 | 0.10~0.40 | 1.80~2.20 | 0.20~0.50 | - | - |

| GB | 9Mn2V | 0.85~0.95 | ≤0.40 | 1.70~2.00 | 0.40 | - | 0.10 |

APPLICATION

O2 steel, as a classic oil quenched die steel, has a wide range of application value in the industrial field. Its excellent comprehensive performance makes it an ideal choice for manufacturing precision tools and wear-resistant components, especially in scenarios that require high hardness and dimensional stability. O2 steel can achieve a working hardness of 58-62HRC through a reasonable heat treatment process, meeting the needs of various cold work molds.

In the field of cold work mold manufacturing, O2 steel is mainly used to produce key components such as punching dies, bending dies, and precision punches. The excellent wear resistance of O2 steel can effectively cope with the repeated stamping operations of metal plates, especially suitable for the processing of small precision parts such as electronic components and hardware accessories. Compared to ordinary carbon tool steel, O2 steel can increase its service life by 3-5 times and significantly reduce the frequency of mold replacement.

O2 steel also performs well in cutting tool manufacturing and is commonly used to make high-precision cutting tools such as blades, drills, and taps. After appropriate heat treatment, its red hardness and wear resistance reach an ideal balance, which can meet the requirements of high-speed cutting. The excellent polishing performance of O2 steel results in a surface finish of Ra0.2 μ m or less during processing.

O2 steel is also widely used in the manufacturing of precision measuring tools and mechanical structural components, such as gauges, templates, and machine tool guides. The small deformation of O2 steel during heat treatment ensures the dimensional stability of the workpiece, while moderate processing performance reduces manufacturing costs.

O2 STEEL CHARACTERISTICS

O2 steel is a low alloy tool steel with superior comprehensive mechanical properties compared to carbon tool steel. Compared with carbon tool steel, O2 steel has higher hardness and wear resistance. In addition, O2 steel has relatively small deformation during quenching and good hardenability. Due to the presence of a certain amount of vanadium in steel, the grain size is refined and the overheating sensitivity of the steel is reduced.

The hardness of O2 steel is relatively high, generally above HRC 60. This allows it to withstand significant cutting forces and wear, extending the service life of the tool. At the same time, the wear resistance of O2 steel is also very good, which can maintain good performance under high-speed cutting and heavy load processing conditions.

O2 steel has good hardenability and can quickly achieve the required hardness. This makes it more convenient to manufacture complex shaped cutting tools. In addition, the deformation of O2 steel during quenching is relatively small, which is beneficial for maintaining the accuracy and surface quality of the cutting tools.

The addition of vanadium element in O2 steel can refine the grain size, improve the strength and toughness of the steel. Meanwhile, vanadium can also reduce the overheating sensitivity of steel, reducing the deformation and damage of cutting tools at high temperatures. This makes O2 steel more stable and reliable under high-speed cutting and high-temperature processing conditions.

O2 steel also has good resistance to tempering and softening, and can maintain high hardness and strength during the tempering process. This makes it more advantageous in manufacturing tools that require multiple tempering treatments.

In short, O2 steel is a low alloy tool steel with excellent performance, which has characteristics such as high hardness, high wear resistance, good hardenability, small deformation, high strength and toughness. These advantages give O2 steel great advantages in manufacturing various complex shaped cutting tools, especially suitable for conditions such as high-speed cutting, heavy load machining, and high-temperature machining. Therefore, O2 steel has been widely used in the tool manufacturing industry.