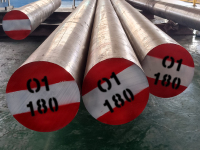

FCS O1 Tool Steel | 1.2510 | 100MnCrW4 | SKS3

O1 mold steel is widely used. O1 steel has good processability, good wear resistance, stable O1 heat treatment performance, small dimensional deformation, but weak toughness and corrosion resistance. It is commonly used in blanking die, punching die, punching die, punching die, etc.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

O1 STEEL

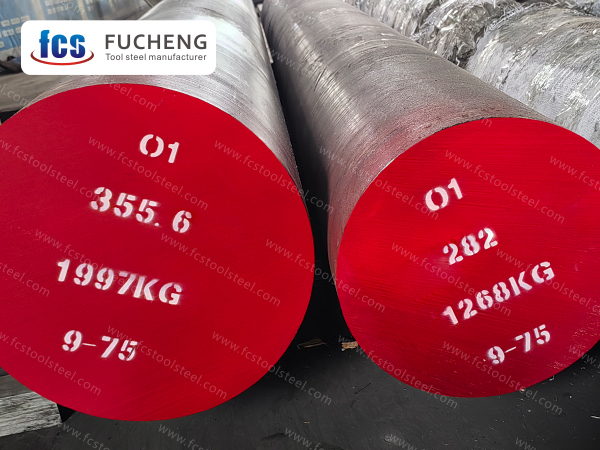

| Brand | FCS |

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤230 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

O1 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | V | W | ||

| ASTM | O1 | 0.85~1.00 | 0.10~0.50 | 1.00~1.40 | 0.40~0.60 | ≤0.30 | 0.40~0.60 |

| DIN/W-Nr. | 100MnCrW4/1.2510 | 0.90~1.05 | 0.15~0.35 | 1.00~1.20 | 0.50~0.70 | 0.05~0.15 | 0.50~0.70 |

| JIS | SKS3 | 0.90~1.00 | ≤0.35 | 0.90~1.20 | 0.50~1.00 | - | 0.50~1.00 |

APPLICATION

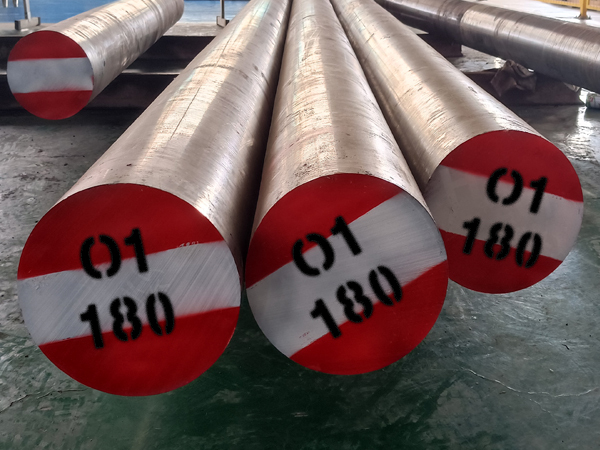

O1 steel has outstanding performance in tool manufacturing, with a high hardness of 60-62 HRC and excellent wear resistance, making it the preferred material for cutting tools such as milling cutters and drills, especially suitable for processing wood and non-ferrous metals. The O1 steel oil quenching process endows it with good dimensional stability and can maintain the sharpness of the cutting edge for a long time.

In terms of mold applications, O1 steel has become an ideal material for cold work molds due to its uniform organizational structure, and is widely used in the manufacturing of hardware molds such as punching molds and bending molds. The low non-metallic content characteristic of O1 steel can also achieve high-precision skin texture reproduction, which is suitable for precision plastic mold manufacturing.

O1 steel is equally important in the field of mechanical parts, commonly used in key components such as bearing rings and precision measuring tools. By adjusting the tempering temperature between 150-400 ℃, O1 steel can precisely optimize its hardness and toughness, meeting the stringent requirements in fields such as automotive and aerospace.

O1 STEEL CHARACTERISTICS

O1 mold steel is a widely used oil quenched hardening tool steel with good wear resistance and processing performance. Due to its stable heat treatment performance, its dimensional deformation is very small. In addition, O1 steel has a good distribution of carbides and small particles, which helps to improve its wear resistance. In addition, the steel has good hardenability and small quenching deformation.

In practical applications, O1 steel exhibits excellent characteristics. Firstly, due to its characteristics of spheroidizing, annealing, and softening of the microstructure, it is easy to carry out cutting processing. Secondly, quenched O1 steel has high hardness and good dimensional stability after tempering. In addition, for hardened steel, softening annealing can be used to improve its cutting performance; The precision mold after rough machining needs to undergo stress relief annealing treatment.

In terms of hardness and wear resistance, ASTM O1 tool steel is considered to have deep hardening characteristics and fine grain structure, exhibiting excellent wear resistance and toughness. In practical applications, O1 steel is often used in hardware molds such as punching dies, stamping dies, bending dies, drawing dies, piercing punches, and finishing dies. However, it is worth noting that although O1 steel performs well in wear resistance and dimensional stability, its toughness and corrosion resistance are relatively weak.

O1 steel is widely used due to its excellent processing performance, wear resistance, and stable heat treatment performance. However, attention should also be paid to the limitations of its strength and corrosion resistance when using it.