- Home

- >

- Products

- >

- M42 high-speed steel

- >

M42 high-speed steel

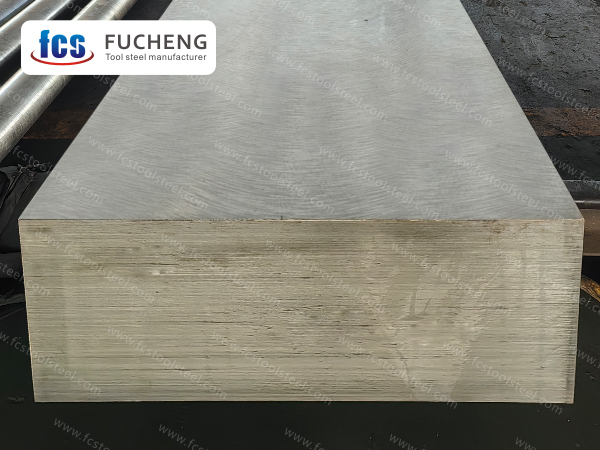

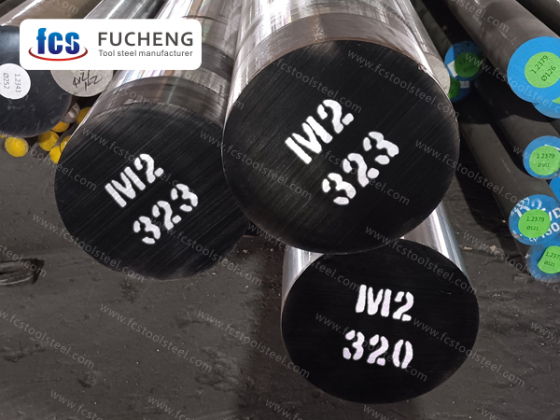

M42 high-speed steel is a high-quality cobalt high-speed steel. Its chemical composition is designed specifically for high hardness and excellent thermal hardness. These characteristics make M42 high-speed steel the best choice for processing high-strength and pre hardened steels, high hardness alloys, and difficult to machine non-ferrous metal superalloys used in the aerospace, petroleum, and power generation industries.

The cutting tool made of M42 high-speed steel can cut iron-based high-temperature alloys, cast high-temperature alloys, titanium alloys, and ultra-high strength steels. Due to its excellent grindability, it can be used to manufacture various high-precision and complex cutting tools.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

M42 HIGH-SPEED STEEL

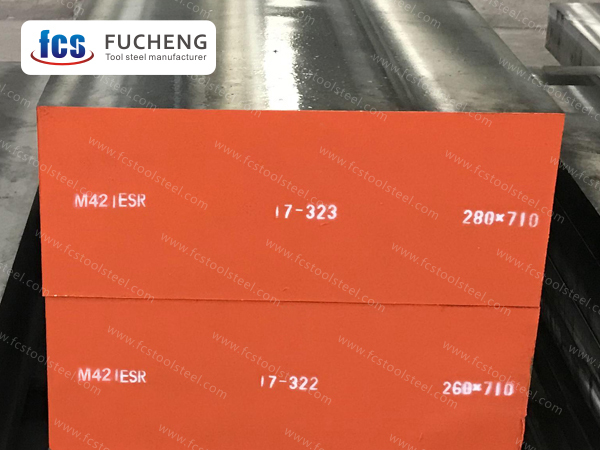

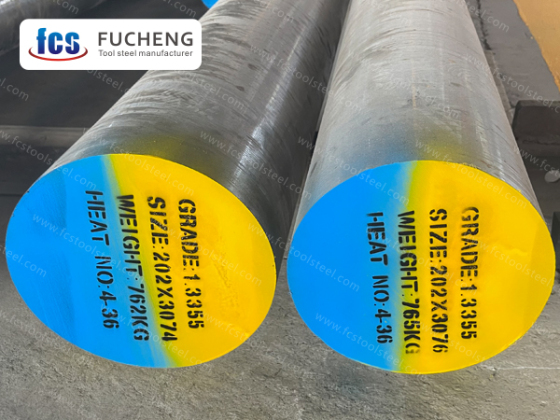

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤300 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

M42 HIGH-SPEED STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||||

| C | Si | Mn | Cr | Mo | V | W | Co | ||

| ASTM | M42 | 1.05~1.15 | 0.15~0.65 | 0.15~0.40 | 3.50~4.25 | 9.00~10.00 | 0.95~1.35 | 1.15~1.85 | 7.75~8.75 |

| DIN/W-Nr. | S2-10-1-8/1.3247 | 1.05~1.12 | ≤0.45 | ≤0.40 | 3.60~4.40 | 9.00~10.00 | 1.00~1.30 | 1.20~1.80 | 7.50~8.50 |

| JIS | SKH59 | 1.00~1.15 | ≤0.50 | ≤0.40 | 3.50~4.50 | 9.00~10.00 | 0.90~1.40 | 1.20~1.90 | 7.50~8.50 |

APPLICATION

M42 high-speed steel exhibits excellent performance in the field of cutting tools due to its high cobalt content and optimized alloy ratio. M42 high-speed steel is particularly suitable for manufacturing high-precision cutting tools such as drill bits, milling cutters, and taps, especially when processing difficult to cut materials such as iron-based high-temperature alloys, titanium alloys, and ultra high strength steels, it can maintain high cutting efficiency for a long time. The excellent red hardness of M42 high-speed steel enables the tool to maintain stable performance even under high-speed cutting or intermittent cutting conditions.

In terms of mold manufacturing, the high wear resistance and impact toughness of M42 high-speed steel make it the preferred material for precision stamping dies and cold forging dies. Typical applications include punch heads for screw forming molds, hexagonal punch heads, and other components that require high stress wear. M42 high-speed steel is also commonly used as a key component in injection molds and die-casting molds, which can significantly extend the service life of molds in high-pressure and high friction environments.

The aerospace and automotive industries extensively use M42 high-speed steel to manufacture specialized machining tools. M42 high-speed steel cutting tools exhibit excellent stability and machining accuracy in the machining of aircraft engine parts such as turbine blades, as well as in the production of high-strength components such as automotive transmission systems. The high temperature resistance of M42 high-speed steel is particularly suitable for the high-speed cutting needs of modern and efficient machining centers, making it an indispensable tool material in the high-end manufacturing field.

M42 HIGH-SPEED STEEL CHARACTERISTICS

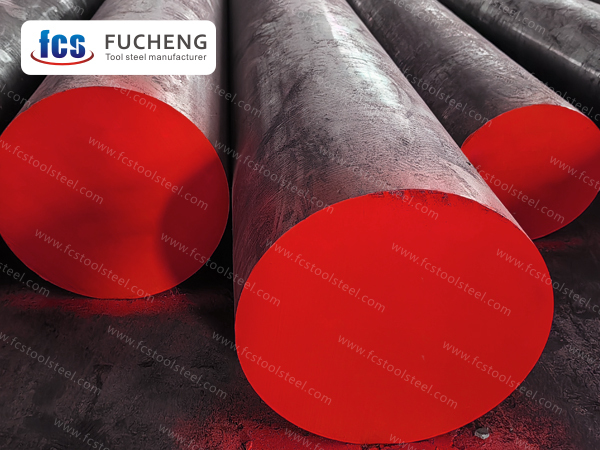

M42 high-speed steel is a high cobalt toughness high-speed steel mainly used for manufacturing high toughness precision wear-resistant metal cold stamping molds, cutting tools, and tool cooling. It has good hardness and thermal hardness, reaching a hardness of 70HRC, while maintaining high hardness at high temperatures, making it easy to grind.

The main component of M42 high-speed steel is high-speed steel, which contains a high proportion of cobalt element. Adding this alloying element gives M42 high-speed steel excellent wear resistance and fatigue resistance. When manufacturing cold stamping molds, the high hardness and wear resistance of M42 high-speed steel can ensure a longer service life of the mold, reduce the frequency of mold replacement, and improve production efficiency. In addition, due to its high hardness and wear resistance, M42 high-speed steel is also suitable for manufacturing cutting tools such as turning and milling cutters. These tools need to have good wear resistance and deformation resistance during high-speed cutting, and M42 high-speed steel can meet these requirements.

In addition to wear resistance and fatigue resistance, M42 high-speed steel also has good thermal hardness. Thermal hardness refers to the ability of a material to maintain its hardness at high temperatures. When manufacturing cutting tools, it is usually necessary to perform cutting in a high-temperature environment, which requires the tool material to have good thermal hardness. M42 high-speed steel can maintain high hardness at high temperatures and is not easily softened or lose cutting performance, thereby ensuring the stability and reliability of the cutting tool.