- Home

- >

- Products

- >

- HMD-1 STEEL

- >

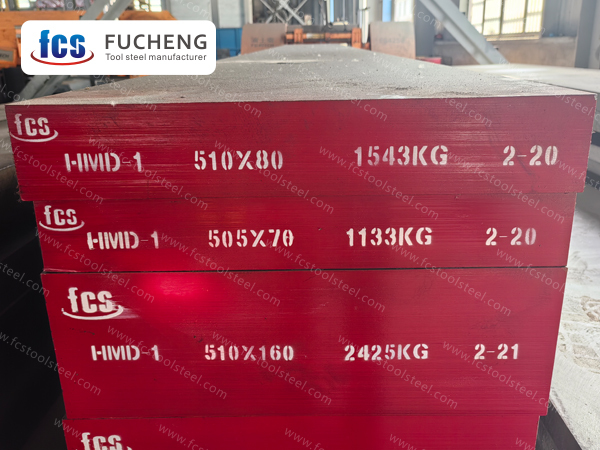

HMD-1 STEEL

HMD-1 steel has high wear resistance and durability. HMD-1 steel contains high alloying elements, so it can still maintain high hardness and cutting performance at high temperatures. Low carbon content, high toughness and plasticity, able to maintain tool integrity under high-strength working conditions.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

HMD-1 STEEL

| Smelting and Manufacture Method: | LF+VD+ESR+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤225 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

HMD-1 STEEL CHEMICAL COMPOSITION

| Steel Grade | Chemical Composition(%) | |||||

| C | Si | Mn | Cr | Mo | V | |

| HMD-1 | 0.80~0.90 | 0.80~1.10 | 0.70~1.00 | 1.80~2.20 | 0.20~0.30 | 0.05~0.10 |

APPLICATION

HMD-1 mold steel is a two-phase extremely fine quenched steel with high strength, toughness, hardness, wear resistance, and high-temperature stability. It is widely used in the manufacturing of high-precision injection molds, extrusion molds, die-casting molds and other industrial fields.

HMD-1 STEEL CHARACTERISTICS

As a new type of high-strength mold steel, HMD-1 steel's characteristics are reflected in multiple dimensions such as material design, performance balance, and industrial applications. HMD-1 steel has significantly improved its toughness performance while maintaining high hardness through optimized alloy ratios and heat treatment processes.

HMD-1 steel adopts a low-carbon high alloy design, with a carbon content controlled in the range of 0.35-0.45%, combined with strong carbide forming elements such as molybdenum and vanadium. The HMD-1 steel composition system not only ensures hardenability but also reduces the generation of large-sized carbides, resulting in a microstructure uniformity improvement of over 40% compared to traditional mold steels.

The heat treatment response of HMD-1 steel exhibits a broad process window, with a quenching temperature range of 880-920 ℃. When using graded quenching, a deformation rate of less than 0.05% can be achieved. After low-temperature tempering at 200-300 ℃, the hardness of HMD-1 steel remains stable at 58-60HRC, and can still maintain above 54HRC even after high-temperature tempering at 500 ℃.

The wear resistance of HMD-1 steel is achieved through nanoscale MC type carbide dispersion strengthening, and its lifespan is 2.3 times that of H13 steel in aluminum alloy die-casting mold testing. The unique wear self-healing mechanism of HMD-1 steel is manifested by the dynamic regeneration of surface oxide film, which is particularly suitable for thermal cycling conditions.

The thermal fatigue resistance of HMD-1 steel has significantly improved, with a 15% increase in thermal conductivity compared to SKD61, and a critical thermal shock temperature difference of 380 ℃. HMD-1 steel effectively solves the problem of cracking failure in die-casting molds by maintaining a tensile strength of 1200MPa at a high temperature of 700 ℃.

The cutting machinability of HMD-1 steel has achieved revolutionary improvement, and a milling speed of 50m/min can be achieved when the annealed hardness is ≤ 220HB. When HMD-1 steel is quenched and hardened using ceramic cutting tools, the surface roughness Ra can reach 0.8 μ m, significantly reducing the subsequent polishing cost of the mold.

The dimensional stability of HMD-1 steel is strengthened through dual aging treatment, and the residual austenite content after cryogenic treatment at -196 ℃ is less than 3%. After six months of use, the size change of HMD-1 steel precision mold does not exceed 0.003mm/m, meeting the requirements for optical component forming.