FCS 3Cr17NiMo-MOD STEEL

3Cr17NiMo MOD STEEl is a kind of pre hardened and tempered plastic tool steel. Excellent corrosion resistance, excellent wear resistance and toughness, good thermal fatigue resistance, uniform material hardness and superior polishing performance.

3Cr17NiMo MOD STEEL is especially suitable for thermoplastic corrosive plastics, transparent and mirror products and molds.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

3Cr17NiMo-MOD STEEL

| Brand | FCS |

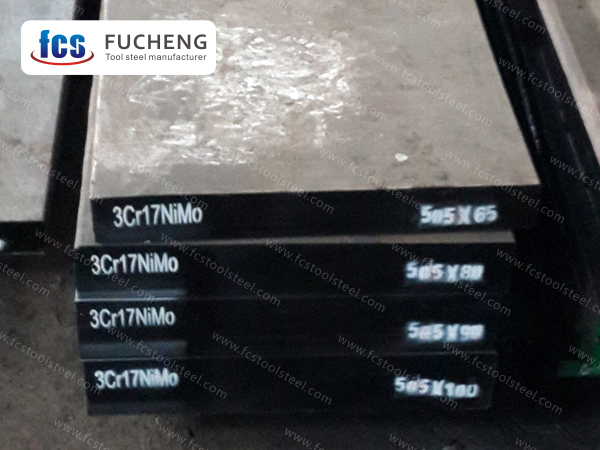

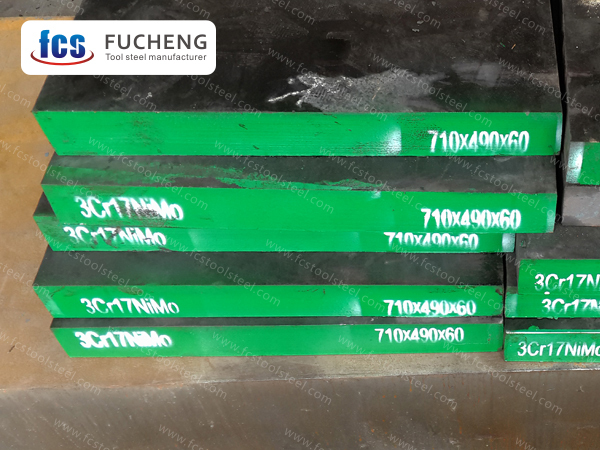

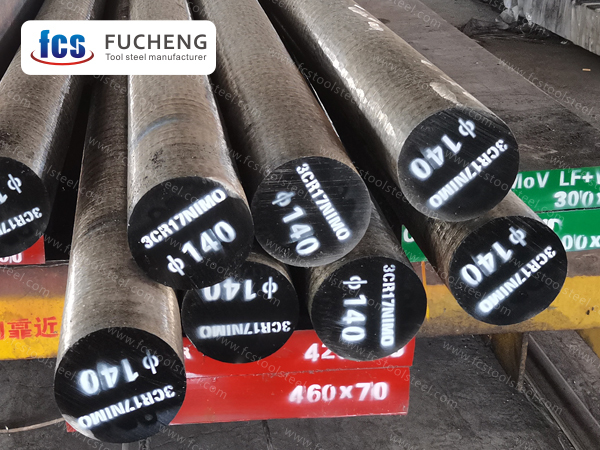

| Smelting and Manufacture Method: | LF+VD+ESR+Forged |

| Delivery Condition: | Annealed/PREHARDEN/QT |

| Delivery hardness: | ≤250 HBS/28-32 HRC/280-310HB |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

3Cr17NiMo-MOD STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | |||||||

| C | Si | Mn | Cr | Mo | Ni | |||

| DIN/W-Nr. | X36CrMo17/1.2316 MOD | 0.33~0.43 | ≤1.00 | ≤1.00 | 15.0~17.0 | 1.00~1.30 | ≤1.00 | |

| GB | 3Cr17NiMo MOD | 0.20~0.32 | ≤0.80 | ≤1.00 | 16.0~18.0 | 0.75~1.25 | 1.10~1.50 | |

APPLICATION

3Cr17NiMo-MOD steel has shown excellent performance in the field of plastic molds, with its mirror polishing performance and corrosion resistance of Ra ≤ 0.01 μ m making it the preferred material for high-end transparent part molds. After oil quenching treatment at 1020-1050 ℃, the hardness of 3Cr17NiMo-MOD steel can reach HRC 45-50, perfectly balancing wear resistance and forming accuracy.

3Cr17NiMo-MOD steel exhibits excellent performance in the field of medical devices, with its chromium molybdenum composite passivation film effectively resisting corrosion from disinfectants and maintaining a hardness of HRC 47-49, meeting the sharpness and hygiene requirements of surgical instruments. The tensile strength of 3Cr17NiMo-MOD steel reaches over 980MPa, significantly extending the lifespan of the instrument.

In chemical equipment, the 16-18% chromium content of 3Cr17NiMo-MOD steel endows it with excellent resistance to chloride ion corrosion, making it suitable for harsh environments such as marine engineering. After tempering at 400-500 ℃, 3Cr17NiMo-MOD steel has an impact toughness of ≥ 50J, making it an ideal material for manufacturing corrosion-resistant valves.

3CR17NIMO-MOD STEEL CHARACTERISTICS

3Cr17NiMo-MOD steel is a high-quality plastic mold steel composed of elements such as carbon, chromium, nickel, and molybdenum, whose content has a significant impact on its properties and characteristics. 3Cr17NiMo-MOD steel has a wide range of applications in the manufacturing of plastic molds, cutting tools, and high-strength mechanical parts, especially in working environments that require high strength, precision, and wear resistance.

3Cr17NiMo-MOD steel has high purity and excellent mirror polishing, which makes it visually outstanding and provides the possibility for advanced precision molds. Secondly, this steel has strong corrosion resistance, which is superior to many other types of mold steels. This characteristic enables 3Cr17NiMo-MOD steel to maintain good performance in harsh working environments, greatly improving its service life in various applications.

In addition, the heat treatment performance of 3Cr17NiMo-MOD steel is excellent, and the size is stable after quenching, tempering, and pre tempering. This makes it easy to perform heat treatment and adjust physical properties to meet different application requirements. At the same time, its wear resistance is also very excellent, comparable to S-136 and 1.2316, and it is easy to weld and repair. This characteristic enables 3Cr17NiMo-MOD steel to provide excellent durability and long-lasting performance when making complex plastic molds.

3Cr17NiMo-MOD steel has become the preferred material for many plastic mold manufacturers due to its high purity, good corrosion resistance, excellent heat treatment performance, and wear resistance. However, although it has many advantages, when selecting and using 3Cr17NiMo-MOD steel, it is still necessary to pay attention to its potential problems and make appropriate treatments.