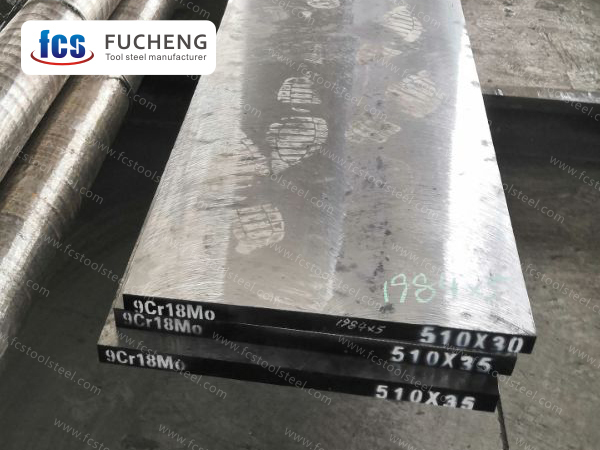

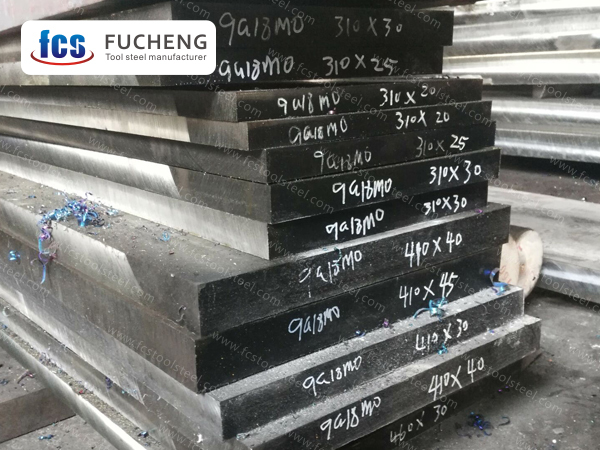

FCS 9Cr18Mo Plastic Mould Steel

9Cr18Mo steel, as a high carbon and high chromium martensitic stainless steel, has shown significant value in multiple industrial fields due to its excellent hardness and corrosion resistance, especially in providing the wear resistance required for high-precision cutting tools in tool manufacturing. The addition of molybdenum significantly enhances the corrosion resistance of the material, ensuring its stability in harsh environments. The 9Cr18Mo steel grade can achieve a balance of strength and toughness through optimized heat treatment processes, and is widely used in core components such as bearings, precision molds, and chemical equipment.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

- Download

9Cr18Mo TOOL STEEL

| Brand | FCS |

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤255 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

9Cr18Mo STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | |||||

| C | Si | Mn | Cr | Mo | ||

| GB | 9Cr18Mo | 0.95~1.10 | ≤0.80 | ≤0.80 | 16.00~18.00 | 0.40~0.70 |

| ASTM | 440C | 0.95~1.20 | ≤1.00 | ≤1.00 | 16.00~18.00 | ≤0.75 |

APPLICATION

9Cr18Mo steel is a high carbon and high chromium martensitic stainless steel with excellent hardness and corrosion resistance. These characteristics make it widely used in fields such as tool manufacturing, bearings, precision molds, chemical equipment, and marine engineering.

Through optimized chemical composition design and heat treatment process, 9Cr18Mo steel can maintain high hardness while also possessing good corrosion resistance and wear resistance. This balanced performance makes it an ideal choice for many industrial applications.

9Cr18Mo steel is particularly suitable for applications that require strict material properties, such as surgical knives, industrial cutting tools, ship bearings, and chemical valves. In these applications, its excellent comprehensive performance can meet high standard industrial requirements.

9Cr18Mo Steel Characteristics

9Cr18Mo steel is a high carbon chromium martensitic stainless bearing steel that has high hardness and wear resistance after quenching, and high dimensional stability at high and low temperatures. In addition, 9Cr18Mo stainless steel also has good processing and heat treatment properties, and its hardness and toughness can be adjusted through quenching and tempering treatment methods.

In terms of physical properties, the density of 9Cr18Mo stainless steel is 7.70g/cm ³, The coefficient of thermal expansion is 10.0 × 10 ^ -6/℃, thermal conductivity of 24.2W/(m · K), specific heat capacity of 0.50J/(g · ℃), and linear expansion coefficient of 15.0 × 10 ^ -6/℃.

In terms of corrosion resistance, 9Cr18Mo stainless steel has significant advantages over ordinary stainless steel. The passivation film formed by high chromium content can effectively resist the erosion of atmosphere, water vapor, and weak acidic and alkaline media, while the addition of molybdenum significantly improves the pitting corrosion resistance of 9Cr18Mo steel in chloride containing ion environments. This characteristic makes it particularly suitable for the manufacturing of critical components in harsh environments such as marine engineering and chemical equipment.

The presence of molybdenum increases the passivation effect of stainless steel, resulting in higher hardness and tempering stability of 9Cr18Mo stainless steel after quenching. Therefore, 9Cr18Mo not only has excellent strength and corrosion resistance, but also can be used under high temperature and high load conditions, demonstrating good heat resistance and wear resistance. These characteristics make it widely used in the manufacturing of automotive engine parts, aerospace equipment, and other fields.