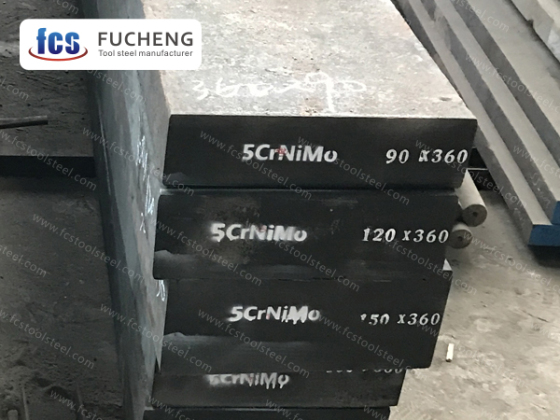

5CrNiMo Hot Work Tool Steel

5CrNiMo tool steel is suitable for manufacturing large and medium-sized hammer forging dies and trimming dies with complex shapes, large impact load and low working temperature.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

5CrNiMo STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤212 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

5CrNiMo STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | |||||||

| C | Si | Mn | Cr | Mo | V | Ni | ||

| GB | 5CrNiMo | 0.50~0.60 | ≤0.40 | 0.50~0.80 | 0.50~0.80 | 0.15~0.30 | - | 1.40~1.80 |

| ASTM | L6 | 0.65~0.75 | 0.10~0.50 | 0.25~0.80 | 0.60~1.20 | ≤0.50 | - | 1.25~2.00 |

| DIN/W-Nr. | 55NiCrMoV6/1.2713 | 0.50~0.60 | 0.10~0.40 | 0.65~0.95 | 0.60~0.80 | 0.25~0.35 | 0.07~0.12 | 1.50~1.80 |

| JIS | SKT4 | 0.50~0.60 | 0.10~0.40 | 0.60~0.90 | 0.80~1.20 | - | 0.05~0.15 | 0.35~0.55 |

APPLICATION

5CrNiMo steel is a traditional hot work die steel, mainly used for manufacturing large and medium-sized forging dies, hot cutting edges and stamping dies, as well as specific plastic and casting dies. 5CrNiMo steel has excellent hardenability and toughness, making it particularly suitable for manufacturing large hammer forging dies and forging press integral dies/inserts with side lengths exceeding 400mm. It is widely used in the forming of high impact load forgings such as automotive crankshafts and connecting rods.

5CrNiMo steel performs well in hot working tools such as hot cutting edge dies and punching dies, and can effectively resist stress cracking. After surface strengthening treatment, 5CrNiMo steel can also be used for glass fiber reinforced plastic injection molds and copper alloy gravity casting molds, balancing wear resistance and thermal fatigue resistance, but its thermal fatigue resistance is slightly inferior to H13 steel.

5CRNIMO STEEL CHARACTERISTICS

5CrNiMo steel, as a classic hot work die steel, is mainly characterized by its comprehensive mechanical properties and process adaptability. The alloy combination of chromium, nickel, and molybdenum in 5CrNiMo steel can maintain stable mechanical properties at working temperatures of 500-600 ℃ through solid solution strengthening and secondary hardening effects.

Under air cooling conditions, 5CrNiMo steel can achieve complete quenching of a 300mm thick section, significantly reducing the risk of deformation during heat treatment of large molds. The unique nickel element in 5CrNiMo steel significantly enhances material toughness, with an impact energy of over 50J, making it particularly suitable for forging die conditions that can withstand severe impacts.

The tensile strength of 5CrNiMo steel, which has undergone appropriate heat treatment, can still be maintained at the level of 800MPa at 550 ℃. This red hardness makes 5CrNiMo steel less prone to collapse or plastic deformation during continuous hot working, ensuring the dimensional stability of the mold.

The thermal fatigue resistance of 5CrNiMo steel is another key characteristic, and its combination of low thermal expansion coefficient (13.5 × 10 ^ -6/℃) and high thermal conductivity (32W/m · K) effectively alleviates the accumulation of thermal stress under rapid cooling and heating conditions.

The wear resistance of 5CrNiMo steel is achieved through chromium carbide dispersion strengthening, and the microhardness can reach 900HV after surface nitriding treatment. This characteristic enables 5CrNiMo steel to resist the erosion of molten metal and extend the service life of aluminum magnesium alloy die-casting molds.

The adaptability of 5CrNiMo steel process is reflected in the compatibility of multiple heat treatment schemes. Conventional 1030 ℃ oil quenching combined with 520 ℃ tempering can achieve the optimal strength toughness ratio, while isothermal quenching process can further refine grain size and enhance isotropy.

In terms of failure mode, 5CrNiMo steel mainly exhibits the propagation of main cracks along the original austenite grain boundaries. By controlling the final forging temperature above 850 ℃, early cracking caused by chain carbides can be effectively avoided.