FCS 1.2746 Tool Steel

1.2746 steel exhibits excellent versatility in both cold and hot working applications. As a high-quality tool steel, it performs well in cold working molds (stamping, stretching, cold heading) for automotive and electronic manufacturing due to its excellent wear resistance and deformation resistance under high loads. Meanwhile, the excellent high-temperature stability and thermal fatigue resistance of 1.2746 steel make it an ideal choice for hot forging and die-casting molds in the aerospace and home appliance industries, significantly extending the service life of the molds while maintaining accuracy under extreme conditions (up to 400 ° C). This dual capability stems from its optimized alloy composition, which has balanced nickel chromium molybdenum vanadium elements.

- Fucheng Steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

- Download

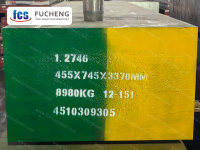

1.2746 TOOL STEEL

| Brand | FCS |

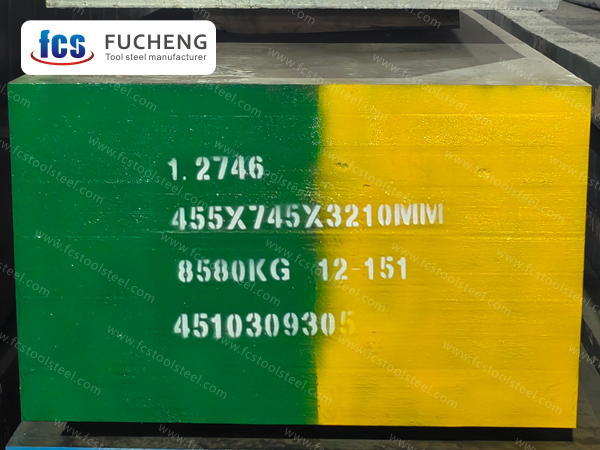

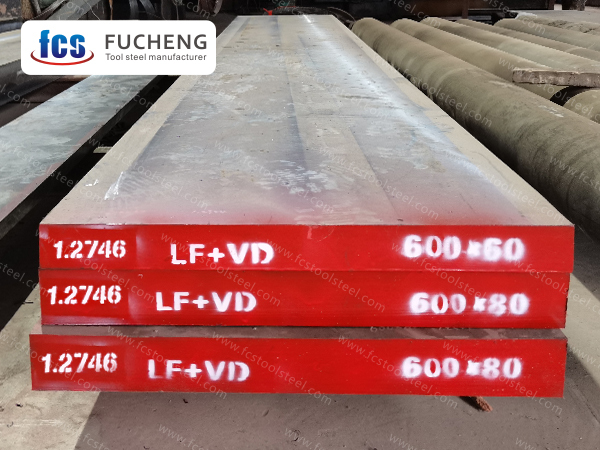

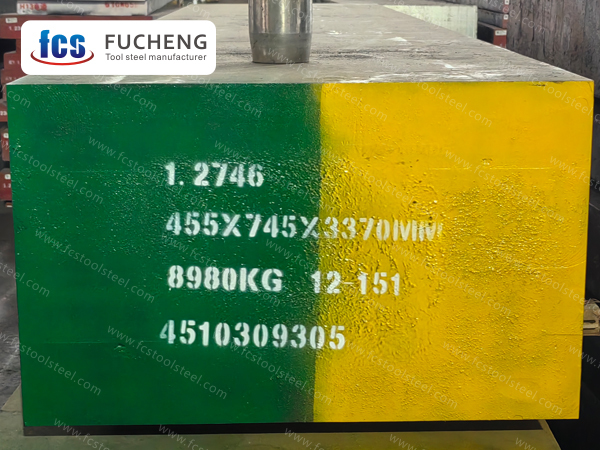

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤295 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

1.2746 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | |||||||

| C | Si | Mn | Cr | Mo | V | Ni | ||

| DIN/W-Nr. | 1.2746 | 0.41~0.49 | 0.15~0.35 | 0.60~0.80 | 1.40~1.60 | 0.73~0.85 | 0.45~0.55 | 3.80~4.20 |

APPLICATION

1.2746 steel is widely used in the field of cold work molds, including stamping molds, stretching molds, cold heading molds, and precision cutting tools, especially suitable for automotive parts stamping and electronic product precision forming scenarios. 1.2746 steel has high wear resistance and toughness, which can effectively resist deformation under high loads, ensuring long-term stable operation of the mold.

1.2746 steel is suitable for the manufacturing of hot work molds in high-temperature working environments, such as hot forging molds and die-casting molds, and can maintain good high-temperature stability and heat fatigue resistance. In the fields of automotive parts, home appliance manufacturing, and aerospace, 1.2746 steel significantly improves the service life and production efficiency of molds.

1.2746 Steel Characteristics

1.2746 steel is an alloy tool steel designed specifically for high-performance cold work molds, with excellent wear resistance and toughness, widely used in industrial manufacturing.

1.2746 Steel contains alloying elements such as carbon, silicon, manganese, chromium, nickel, molybdenum, and vanadium. Chromium and molybdenum improve hardenability and wear resistance, nickel enhances toughness, and vanadium helps refine grain size.

1.2746 steel needs to undergo normalizing or annealing pretreatment, and then optimize its performance through quenching and tempering processes. Standard heat treatment ensures that the material obtains the optimal combination of hardness and toughness.

1.2746 steel has high tensile strength and yield strength, while maintaining good impact toughness and plastic deformation ability, making it suitable for high load cold working environments.

1.2746 steel has good thermal stability and thermal conductivity, and can maintain dimensional stability under temperature changes, ensuring long-term reliable operation of the mold.

1.2746 steel is mainly used for manufacturing cold work tools such as stamping molds, stretching molds, and cold heading molds, and is particularly suitable for precision forming and processing of automotive components and electronic products.

The cutting performance of 1.2746 steel is good in the annealed state, but parameters need to be optimized for high hardness machining; Welding requires preheating and post weld tempering treatment to avoid cracking.