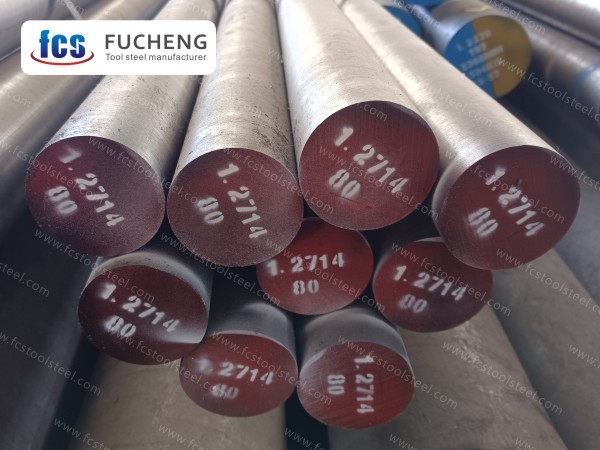

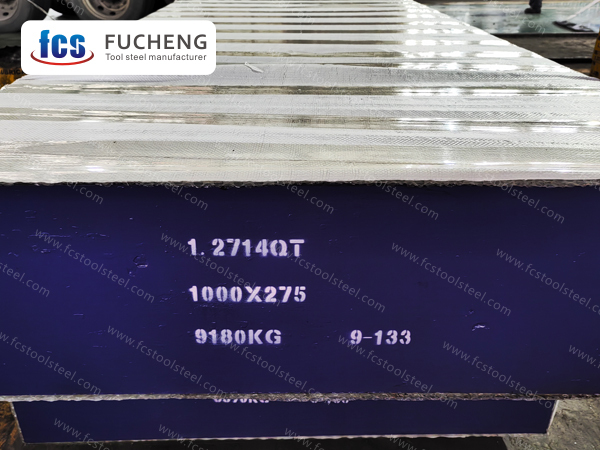

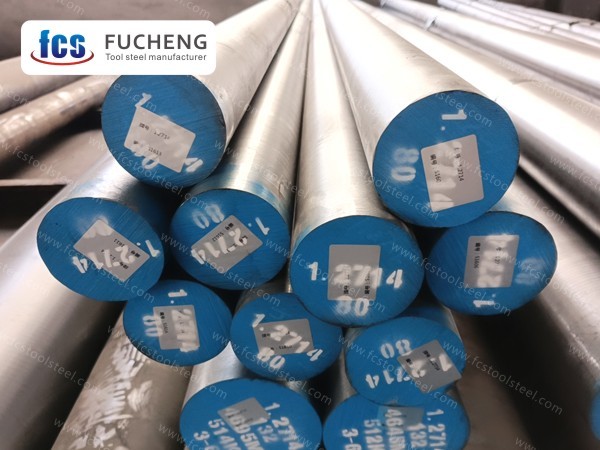

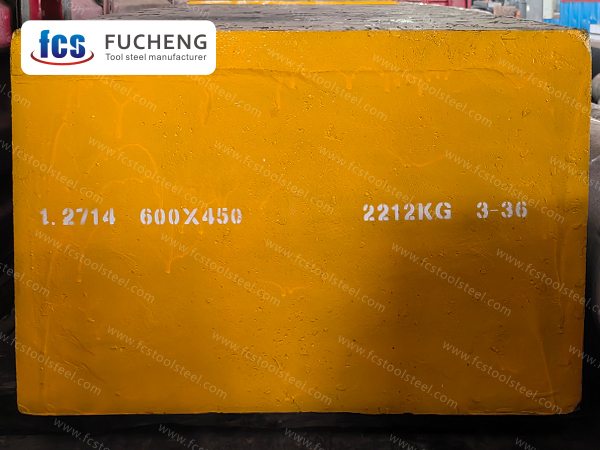

FCS 1.2714 Hot Work Tool Steel

1.2714 steel material exhibits excellent thermal fatigue resistance and corrosion resistance in die casting applications, and its microstructural stability enables it to maintain performance under long-term thermal cycling conditions. Compared to similar materials, 1.2714 steel has better resistance to softening and processing adaptability, making it the preferred material for high-end hot work molds.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

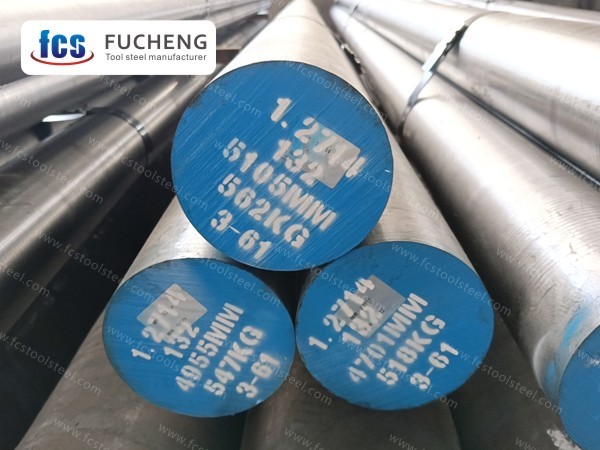

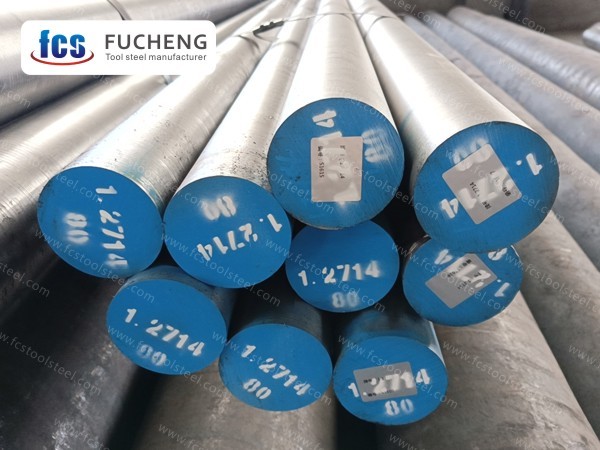

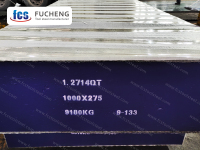

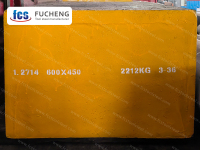

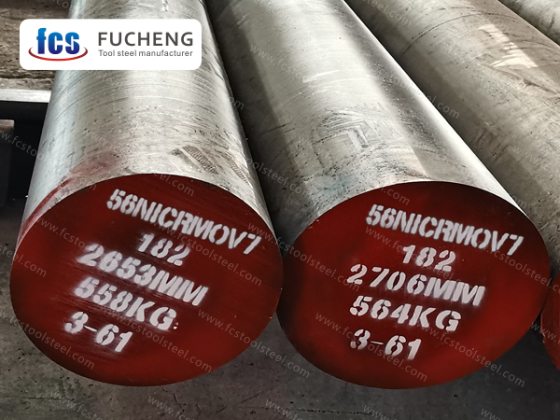

1.2714 TOOL STEEL

| Brand | FCS |

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤241 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

1.2714 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | |||||||

| C | Si | Mn | Cr | Mo | V | Ni | ||

| DIN/W-Nr. | 56NiCrMoV7/1.2714 | 0.50~0.60 | 0.10~0.40 | 0.65~0.95 | 1.00~1.20 | 0.45~0.55 | 0.07~0.12 | 1.50~1.80 |

| ASTM | 6F3 | 0.55 | 0.85 | 0.60 | 1.00 | 0.75 | 0.10 | 1.00 |

| GB | 5CrNiMoV | 0.50~0.60 | ≤0.35 | 0.50~0.80 | 0.80~1.10 | 0.35~0.50 | 0.10~0.30 | 1.40~1.80 |

APPLICATION

1.2714 steel is mainly used in the manufacturing of die-casting molds (aluminum/magnesium alloys), heavy-duty forging dies (such as automotive crankshafts, connecting rods, and other components that withstand large tonnage impacts), hot extrusion tools, and high-precision plastic injection molds; 1.2714 steel can maintain stable high hardness, excellent thermal fatigue resistance, and impact toughness under high temperature conditions (such as 300-600 ℃) through optimized alloy ratios and heat treatment processes. 1.2714 steel is particularly suitable for harsh environments that can withstand severe thermal cycles and high-pressure loads, significantly extending the service life of molds.

1.2714 Steel Characteristics

1.2714 steel can maintain stable mechanical properties in sustained high temperature environments in terms of high-temperature strength. This characteristic makes it particularly suitable for high-temperature applications such as die-casting molds.

The outstanding advantage of 1.2714 steel is its resistance to thermal fatigue, as its microstructure can effectively resist thermal stress caused by drastic temperature changes. This feature significantly extends the service life of the mold under rapid cooling and heating conditions.

The corrosion resistance of 1.2714 steel is attributed to its special alloy composition design, which enables the formation of a dense protective layer on the surface of the mold. This characteristic is particularly important in corrosive environments such as aluminum alloy die-casting.

In terms of toughness performance, 1.2714 steel has excellent impact resistance while maintaining high hardness. This balance enables it to withstand mechanical impact loads during the production process.

In terms of processing performance, 1.2714 steel exhibits good machinability in the annealed state. This feature reduces the processing difficulty and cost in the mold manufacturing process.

1.2714 steel has minimal deformation during heat treatment, making it particularly suitable for precision mold manufacturing. This feature ensures the dimensional accuracy and reusability of the mold.

In terms of anti softening ability, 1.2714 steel performs well and can maintain working hardness for a long time. This feature is crucial for extending the service life of molds.