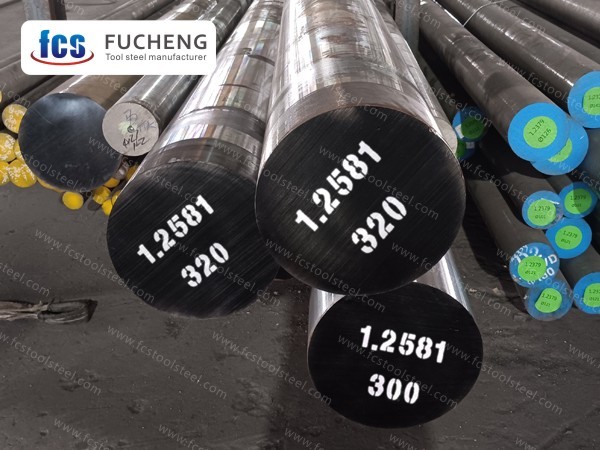

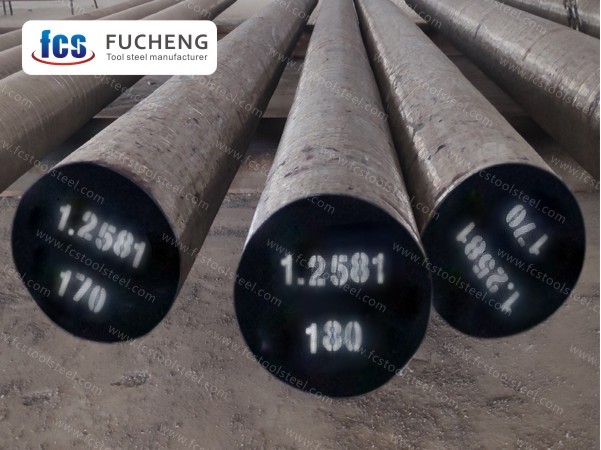

1.2581 Hot Work Tool Steel

1.2581 hot work mold steel is a commonly used die-casting mold steel. 1.2581 steel has high strength and hardness, good resistance to cold and hot fatigue, and good hardenability.

- fucheng steel

- China

- 1 Month

- 2000 Tons/Month

- Information

- Video

- Download

1.2581 TOOL STEEL

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤240 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

1.2581 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | V | W | ||

| DIN/W-Nr. | X30WCrV9-3/1.2581 | 0.25~0.35 | 0.15~0.30 | 0.20~0.40 | 2.50~2.80 | 0.30~0.40 | 8.00~9.00 |

| GB | 3Cr2W8V | 0.30~0.40 | ≤0.40 | ≤0.40 | 2.20~2.70 | 0.20~0.50 | 7.50~9.00 |

| ASTM | H21 | 0.26~0.36 | 0.15~0.50 | 0.15~0.40 | 3.00~3.75 | 0.30~0.60 | 8.50~10.0 |

APPLICATION

1.2581 steel is suitable for making punch and die without impact load under high temperature and high stress, such as die casting die, hot extrusion die, precision forging die and non-ferrous metal forming die.

1.2581 STEEL CHARACTERISTICS

1.2581 steel is a type of hot working tool steel mainly used for manufacturing high load tool components such as molds, extrusion molds, and hot stamping molds. This type of steel has high hardness and thermal stability, good wear resistance and hardenability, as well as good fatigue resistance.

The high hardness of 1.2581 steel provides excellent durability when manufacturing high-load tools. When working at high temperatures, the hardness of the steel does not significantly decrease, which helps to maintain the shape and dimensional accuracy of the tool. In addition, high hardness also means that the tool is less prone to wear and tear during use, thereby extending its service life.

1.2581 steel has good wear resistance. When manufacturing tools, steel needs to withstand a lot of friction and wear. If the wear resistance of steel is insufficient, tools are easily damaged. However, the wear resistance of 1.2581 steel is very good, which can effectively resist friction and wear, thereby ensuring the reliability and durability of the tool.

1.2581 steel has excellent hardenability. When manufacturing tools, steel usually needs to be quenched to improve its hardness and strength. However, if the hardenability of the steel is insufficient, problems such as cracks and deformation may occur during the quenching process. These issues can affect the performance and lifespan of the tool. Fortunately, the quenching resistance of 1.2581 steel is very good, which can effectively prevent problems during the quenching process.

1.2581 steel has good fatigue resistance. When manufacturing tools, steel needs to withstand a large amount of periodic loads. If the fatigue resistance of steel is insufficient, tools are prone to fatigue fracture during use. However, the fatigue resistance of 1.2581 steel is very good, which can effectively resist fatigue fracture, thereby ensuring the safety and reliability of the tool.

In addition to the above characteristics, 1.2581 steel also has good machinability and weldability. This makes it more convenient and economical for steel to manufacture tools with complex shapes. In addition, 1.2581 steel also has high thermal conductivity and low coefficient of thermal expansion, which helps improve the cooling efficiency and dimensional stability of the tool.